About Us

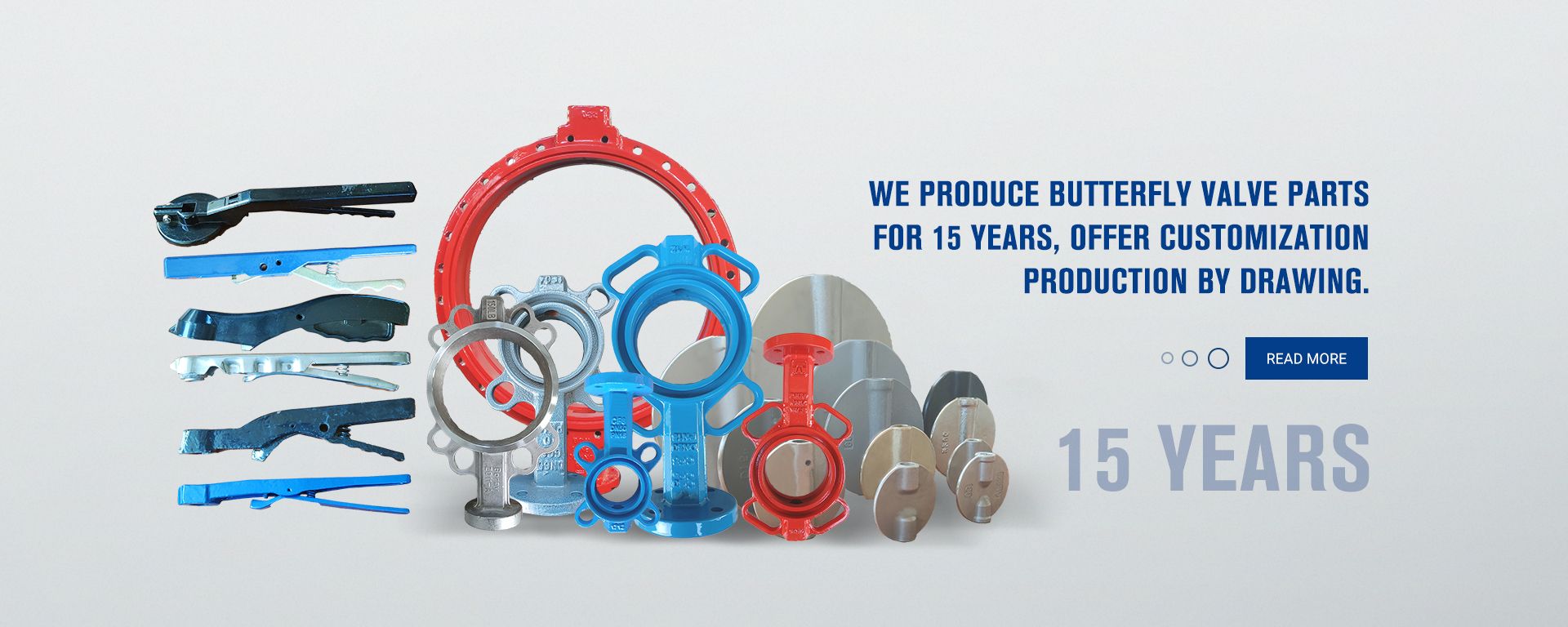

Tianjin Zhongfa Valve Co., Ltd.

Tianjin Zhongfa Valve Co., Ltd. Founded in 2006, a valve manufacturer in Tianjin, China. Mainly produce butterfly valve, gate valve, check valve, knife gate valve etc. We keep in high efficiency and strictly management of quality control, provide timely and effective pre-sale, sale and after-sales service in order to achieve effectiveness and customer satisfaction. We have gotten the ISO9001, CE Certification.

Blogs

Keep abreast of the latest company and industry news

-

What Is The Difference Between Gate Valve And Butterfly Valve?

Gate valves and butterfly valves are two very commonly used valves. They are very different in terms of their own structures, usage methods, and adaptability to working conditions. This article w...

-

Analysis of the four main causes of leakage of ball valves and measures to deal with them

Through the analysis of the structural principle of the fixed pipeline ball valve, found that the sealing principle is the same, using the “piston effect” principle, and only the sealing structure is different. Valve in the application of the problem is mainly manifested in different ...

-

What problems should we pay attention to in the soft gate valve procurement process?

I often encounter customer inquiries as below: "Hi, Beria, I need gate valve, can you quote for us?" Gate valves are our products, and we are very familiar with them. Quotation is definitely no problem, but how can I give him a quotation based on this inquiry? How to quo...

More Products

Our valves are compliance with valve international standard of ASTM, ANSI, ISO, BS, DIN, GOST, JIS, KS and so on.

NEWSLETTER

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.