Wafer Type Fire Signal Butterfly Valve

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN300 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

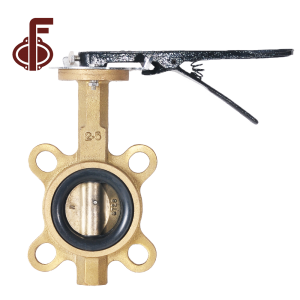

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

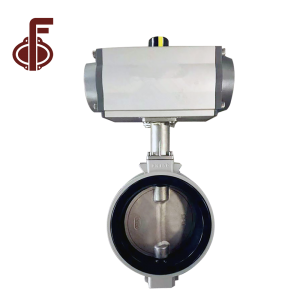

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Our Wafer Butterfly Valve Family

Wafer Butterfly Valve Body Type

Hard Seat Wafer Butterfly Valve

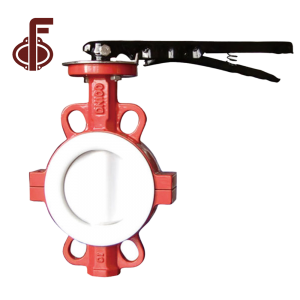

Soft Seat Wafer Butterfly Valve

EPDM Full Lined Wafer Butterfly Valve

PTFE Seat Wafer Butterfly Valve

PTFE Full Lined Wafer Butterfly Valve

Pneumatic Wafer Butterfly Valve

Electrical Wafer Butterfly Valve

Bronze Wafer Butterfly Valve

Product Advantage

Butterfly valves are used in petroleum, chemical, food, medicine, pharmaceutical, hydropower, ships, water supply and drainage, smelting, energy and other pipelines, and can be used as the regulation of various corrosive, non-corrosive gas, liquid, semi-fluid and solid powder pipelines and containers and interception equipment. This Butterfly Valve For Fire Fighting System is especially widely used in high-rise building fire protection systems and other piping systems that need to display valve switching status.

The fire signal wafer butterfly valve is connected between the butterfly valve and the signal terminal. Based on manual installation of the valve, the XD371J signal butterfly valve wafer-type electric switch box is added, including micro switches; cams; terminal boards; input cables; and structural components. There is a micro switch between on and off. When the fire signal wafer butterfly valve switch is opened and closed, right place, it will send out an electrical signal. The electrical switch box is fully sealed, and the shell has no sealing ring, which can be used directly outdoors. It can control the medium in the pipeline and is also an accessory of the sprinkle system in fire engineering.

Fire Signal Wafer Butterfly Valve 1. Material: cast iron, nitrile rubber

A butterfly valve is a valve that can be used to isolate or regulate flow. The closing mechanism takes the form of a disc. The operation is similar to a ball valve, allowing for quick closure. Butterfly valves are often favored because they are lower cost and lighter than other valve designs, meaning less support is required. The valve disc is located in the center of the pipe, and through the valve disc is a stem that connects to the valve's external actuator. The rotary actuator rotates the valve disc either parallel or perpendicular to the fluid. Unlike ball valves, the disc is always present in the fluid, so there is always a pressure drop in the fluid regardless of valve position.