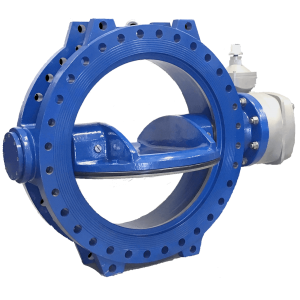

Concentric Cast Iron Full Lined Butterfly Valve

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN300 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

Product Advantage

The valve seat is wide edge seat, sealing gap is wider than regular type, makes the sealing for connection easier. Wider seat also easy to install than narrow seat. The stem direction of the seat has lug boss, with O ring on it, archive the second sealing of the valve.

The valve seat with 3 bushing and 3 O ring, helps supporting the stem and guarantee the sealing.

Each valve should be cleaned by ultra-sonic cleaning machine, in case of contaminant left inside, guarantee the cleaning of the valve, in case of pollution to the pipeline.

Handle of the valve use ductile iron, is anti-corrosion than regular handle. Spring and pin use ss304 material. Handle part use semicircle structure, with good touch feeling.

Butterfly valve pin use modulation type, high strength, wear-resisting and safe connection.

Non-pin stem design adopts anti-blowout structure, the valve stem adopt double jump ring, not only can compensate the error in installation, but also can stop the stem being blow off.

After natural cooling, the adhesive of the powder is higher than regular type, guarantee there’s no color change in 36 months.

Pneumatic actuators adopt double piston structure, with high precision and effective, and stable output torque.

Body Test: The valve body test use 1.5 times pressure than standard pressure. The test should be done after installation, the valve disc is half close, called body pressure test. The valve seat uses 1.1 times pressure than standard pressure.

Company Advantage

Price Advantage: Our price is competitive because we process valve parts by ourselves.

QC: Our regular customers have been working with us more than 10 years as we always keeping our high-level QC for our products.

Our valves are compliance with valve international standard of ASTM, ANSI, ISO, BS, DIN, GOST, JIS, KS and so on. Size DN40-DN1200, nominal pressure: 0.1Mpa~2.0Mpa, suitable temperature:-30℃ to 200℃. The products are suitable for non-corrosive and corrosive gas, fluid, semi-fluid, solid, powder and other medium in HVAC, fire control, water conservancy project, water supply and drainage in urban, electric powder, petroleum, chemical industry, and so on.