Two Shaft Replaceable Seat Double Flange Butterfly Valve

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN4000 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

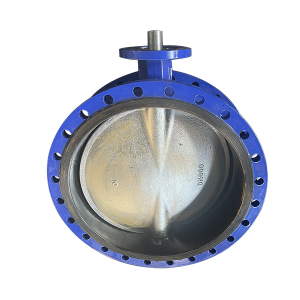

SS CF8 Replaceable Seat Butterfly Valve

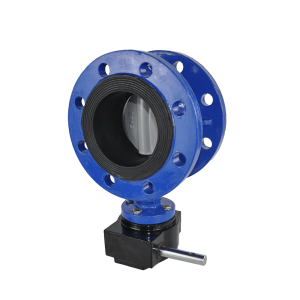

DI Replaceable Seat Butterfly Valve

Ductile Iron Vulcanized Seat Butterfly Valve

Product Advantage

Body Materials: Typically constructed from ductile iron (often coated with fusion-bonded epoxy for corrosion resistance), carbon steel, stainless steel, or special alloys like aluminum bronze, Monel, or duplex stainless steel for corrosive media.

Disc Materials: The disc is commonly made from stainless steel (e.g., CF8M), ductile iron, or coated with materials like nylon or PTFE for enhanced corrosion resistance and sealing.

Shaft Materials: High-strength stainless steel (e.g., SS431, SS316) or corrosion-resistant alloys ensure durability and reliable torque transmission.

Coatings: Epoxy coatings (e.g., Aksu epoxy resin) or fusion-bonded epoxy (FBE) protect the valve body from corrosion, especially in water or seawater applications.

The valve is designed for bidirectional flow and sealing, making it versatile for applications where flow direction may change.

Complies with API 609, AWWA C504, EN 593, ISO 5752, and flange standards like ASME B16.5, EN 1092-1, or JIS B2220.

EPDM seats are certified by WRAS for potable water applications.

Company Advantage

Our valves are compliance with valve international standard of ASTM, ANSI, ISO, BS, DIN, GOST, JIS, KS and so on. Size DN40-DN1200, nominal pressure: 0.1Mpa~2.0Mpa, suitable temperature:-30℃ to 200℃. The products are suitable for non-corrosive and corrosive gas, fluid, semi-fluid, solid, powder and other medium in HVAC, fire control, water conservancy project, water supply and drainage in urban, electric powder, petroleum, chemical industry, and so on.

Price Advantage: Our price is competitive because we process valve parts by ourselves.

We think “Customer satisfaction is our ultimate goal.” Depending on our advanced technology, complete quality control and good reputation, we will offer more high-quality valve products.