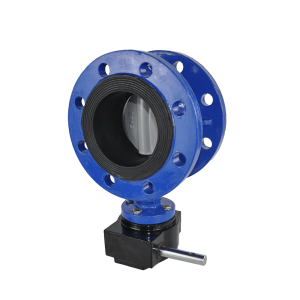

Electric WCB Vulcanized Seat Flanged Butterfly Valve

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN1800 |

| Pressure Rating | Class125B,Class150B,Class250B |

| Face to Face STD | AWWA C504 |

| Connection STD | ANSI/AWWA A21.11/C111 Flanged ANSI Class 125 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Ductile Iron,WCB |

| Disc | Ductile Iron,WCB |

| Stem/Shaft | SS416, SS431 |

| Seat | NBR, EPDM |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

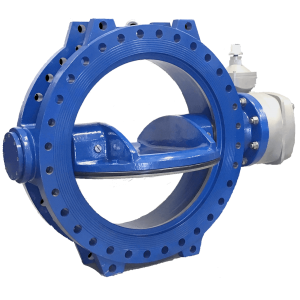

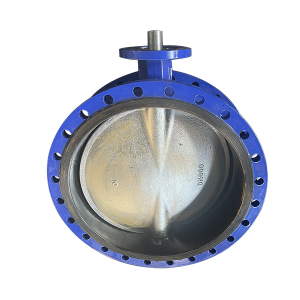

Product Display

Product Advantage

The main features of the vulcanized seat dual half-shaft flange butterfly valve:

1. Dual half-shaft design: The valve opening and closing process is more stable, reducing fluid resistance and improving flow control accuracy.

2. Vulcanized valve seat: Made of special vulcanized material, it has good wear resistance and sealing performance, ensuring long-term stable operation of the valve.

3. Flange connection: Standard flange connection is used to facilitate connection with other equipment and has a wide range of applications.

4. Various actuators: electric actuators, but other actuator also can be selected according to user needs to meet different operating needs,such as worm gear, pneumatic, etc.

5. Scope of application: widely used in pipeline flow control in petroleum, chemical industry, metallurgy, water treatment and other fields.

6. Sealing performance: When the valve is closed, it can ensure complete sealing and prevent fluid leakage.

7. Easy maintenance: Simple structure, easy to maintain and repair, reducing operating costs.