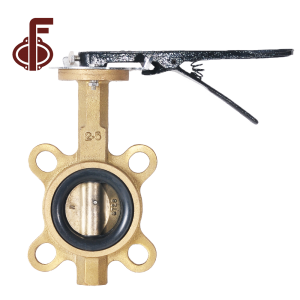

Butterfly valves are a family of quarter-turn rotational motion valves used in pipelines, there are many butterfly valve types. Usually, different types of butterfly valves are classified by connections, materials, structure form, manufacturing process, and so on. ZFA is one of the famous wafer butterfly valve manufacturers, flange butterfly valve manufacturers, and lug butterfly valve manufacturers in China.

Butterfly valve types by Connection, are four types.

5. Weld butterfly valve

Butterfly valve types by valve body materials are below five types.

1. Ductile iron butterfly valve

2. Carbon steel butterfly valve

3. Stainless steel butterfly valve

4. Supper stainless steel butterfly valve

Butterfly valves types by manufacturing process for valve bodies are below three types

1. Casting butterfly valve

2. Welding butterfly valve

3. Forging butterfly valve

Casting

Welding

Forging

Types by structure form, are below two types.

1. Centerline Butterfly Valve

a. Advantages: Simple structure and easy to manufacture, economic;

b. Disadvantages: The butterfly plate and the valve seat are always in the state of extrusion and scraping, the resistance distance is large and the wear is fast.

c. Applications: Widely used in many fields such as petroleum, chemical, metallurgy, and hydropower.

2. Eccentric Butterfly Valve

a. Advantages: Stand high temperature and pressure, Extend the life of the valve seat

b. Disadvantages: Expensive and more complex to manufacture

c. Applications: Widely used in the fluid piping system of water supply and drainage, sewage, construction, petroleum, chemical, light textile, paper making, hydropower, metallurgy, energy, and other projects.

Let's analyze the relevant principles and development history of the Centerline butterfly valve and eccentric butterfly valve in detail.

The centerline Butterfly Valve is characterized by the center of the stem axis, the center of the butterfly plate, and the center of the body in the same position, as a typical centerline valve. The concentric butterfly valve, is usually from size DN50 to DN2200, The sealing of the center line butterfly valve is soft, so it is a low-temperature and low-pressure valve. The ductile iron butterfly valve is one of the concentric butterfly valves

Pressure: DN<DN300, Max pressure is PN25; DN<DN800 Max pressure is PN16;DN< DN1200, max pressure PN10; DN>1200, Max pressure PN6;

Temperature: According to the sealing materials, For example, NBR, Max temperature: 100℃, EPDM, Max temperature:150℃; FRM, Max temperature:200℃; SBR, Max temperature:100℃; CR, Max temperature:100℃; NR, Max temperature:70℃; HR, Max temperature:100℃; UR, Max temperature:40℃.

For the eccentric butterfly valve, they are three types

a. Single Eccentric Butterfly Valve

b. Double eccentric butterfly valve

The history of the eccentric butterfly valve type

The single eccentric butterfly valve is a type of butterfly valve produced to solve the problem of squeezing the butterfly plate and the valve seat in the middle line butterfly valve. The stem axis deviates from the center of the butterfly valve so that the lower end of the butterfly valve no longer becomes the axis of rotation, which disperses and reduces the transitional squeezing of the upper and lower ends of the butterfly plate and the valve seat.

The double offset butterfly valve is one of the butterfly valve types, the stem axis is off both the center of the butterfly plate and the body's center. The effect of double eccentricity enables the butterfly plate to quickly disengage from the seat after the valve is opened, which helps to eliminate excessive squeezing and scraping between the butterfly plate and the seat and improves the seat life. The significant reduction of scraping makes it possible to use metal seats for double eccentric butterfly valves, which can be used in high-temperature applications.

The triple eccentric butterfly valve is a type of butterfly valve, for the stem axis position deviation at the same time, making the conical axis of the butterfly plate sealing surface deviate from the body's cylindrical axis, the sealing surface of the butterfly plate is elliptical, the shape of the sealing surface is therefore asymmetric, one side is inclined to the body centerline, the other side is parallel to the body centerline. Three eccentric butterfly valves fundamentally transform the sealing surface, no longer position sealing, but torsion sealing, relying on the contact surface of the valve seat to achieve the sealing effect, solving the problem of zero leakage of the metal valve seat. Since the contact surface pressure and medium pressure are proportional, it also solves the problem of high pressure and high temperature, and the butterfly valve is more widely used.