Wafer check valves are also known as backflow valves, backstop valves, and backpressure valves. These kinds of valves are automatically opened and closed by the force generated by the flow of the medium itself in the pipeline, belonging to a kind of automatic valve.

The check valve is to rely on the flow of the medium itself and automatically opens and closes the valve flap, used to prevent the medium backflow valve, also known as the check valve, check valve, backflow valve, and back pressure valve. The check valve belongs to a kind of automatic valve, its main role is to prevent the media backflow, prevent the pump and drive motor reversal, as well as container media discharge. Check valves can also be used to give the pressure may rise to more than the system pressure of the auxiliary system to provide a supply pipeline. The check valve can be divided into a swing check valve (according to the center of gravity rotation) and a lift check valve (moving along the axis).

First, the use of clip-on check valve check valve installed in the piping system, its main role is to prevent the media backflow, check valve is a kind of automatic valve relying on the media pressure to open and close. Clamp check valve is suitable for nominal pressure PN1.0MPa ~ 42.0MPa, Class150 ~ 25000, nominal diameter DN15 ~ 1200mm, NPS1/2 ~ 48, operating temperature -196 ~ 540 ℃ of the various pipelines, used to prevent the media backflow. Through the selection of different materials, can be applied to water, steam, oil, nitric acid, acetic acid, strong oxidizing media and uric acid and other media.

The main materials of the wafer check valve are carbon steel, low-temperature steel, duplex steel(SS2205/SS2507), titanium alloy, aluminum bronze, Inconel, SS304, SS304L, SS316, SS316L, chrome-molybdenum steel, Monel (400/500), 20# alloy, Hastelloy and other metal materials.

Third, the standards and norms of the wafer check valve

Design:API594、API6D、JB/T89372、

Face to face length:API594、API6D、DIN3202、JB/T89373、

Pressure rate and temperature:ANSI B16.34、DIN2401、GB/T9124、HG20604、HG20625、SH3406、JB/T744、

Test and inspection standard:API598、JB/T90925

Piping Flanges:JB/T74~90、GB/T9112-9124、HG20592~20635、SH3406、ANSI B 16.5、DIN2543-2548、GB/T13402、API605、ASMEB16.47

Fourth, the structural characteristics of the pinch check valve

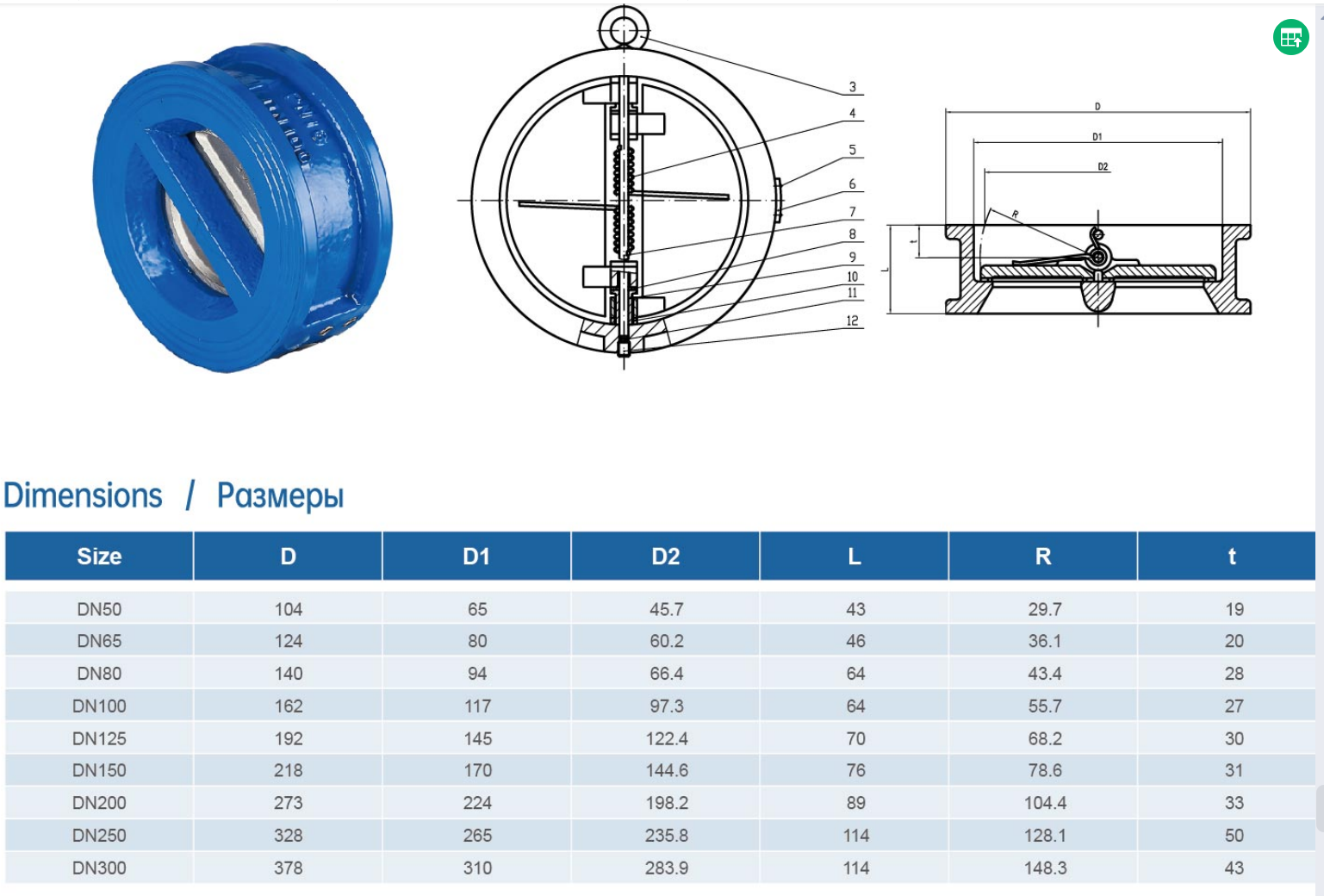

1.Short structure length, its structure length is only 1/4~1/8 of the traditional swing flange check valve.

2. small volume, light weight, its weight is only the traditional flange check valve 1/4 ~ 1/2

3. valve flap closes quickly, water hammer pressure is small

4. Horizontal or vertical piping can be used, easy to install

5. Smooth flow path, low fluid resistan

6.Sensitive action, good sealing performance

7.Disc stroke is short, closing impact is small

8.The overall structure is simple and compact, and the shape is beautiful

9. Long service life and reliable performance

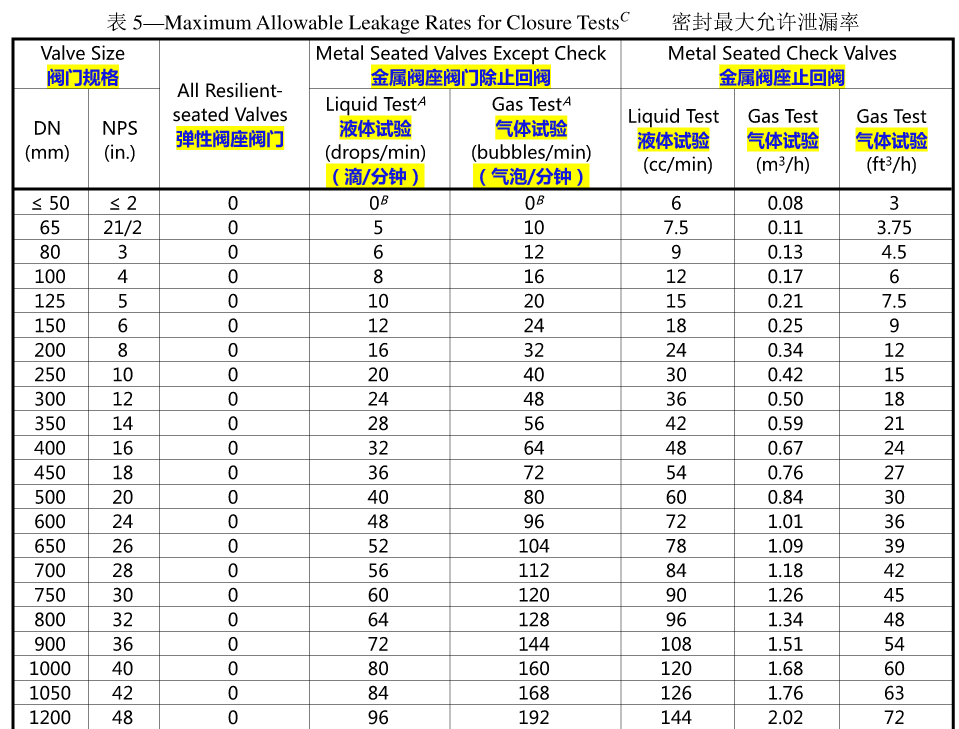

five. The sealing performance of the wafer check valve The soft-sealed wafer check valve can achieve zero leakage, but the hard-sealed wafer check valve is not a zero-leakage valve. It has a certain leakage rate. According to the inspection standard of API598, for the check valve with metal seat, for the size of DN100, the liquid leakage rate per minute is 12CC.