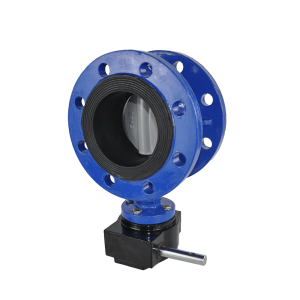

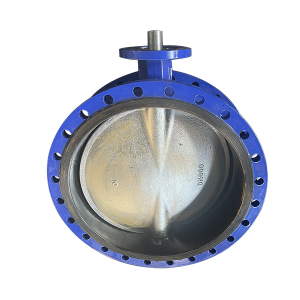

DN1500 Vulcanized EPDM Seat Large Flange Butterfly Valve

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN4000 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

Product Advantage

1.DN1500 (approx. 60 inches) a large diameter valve, used in water treatment plants, power plants, large HVAC systems, and industrial piping for gases or liquids.

2. Vulcanized seat made of EPDM, Nitrile, Viton bonded (vulcanized) to the valve body or a metal seat ring during manufacturing. No seat movement or compression set issues compared to some pressed-in seats.

3. Common Applications

Water supply & distribution

Cooling water systems in power plants

Wastewater treatment

HVAC systems (large air handling units)

Industrial process lines (non-abrasive media)

4. Important Considerations for DN1500 Valves

Weight – very heavy, requires proper support in piping.

Actuation – usually operated with a gear operator or an electric/hydraulic/pneumatic actuator due to size.

Installation – ensure proper flange alignment to avoid seat damage.

Company Advantage

Our valves are compliance with valve international standard of ASTM, ANSI, ISO, BS, DIN, GOST, JIS, KS and so on. Size DN40-DN1200, nominal pressure: 0.1Mpa~2.0Mpa, suitable temperature:-30℃ to 200℃. The products are suitable for non-corrosive and corrosive gas, fluid, semi-fluid, solid, powder and other medium in HVAC, fire control, water conservancy project, water supply and drainage in urban, electric powder, petroleum, chemical industry, and so on.

Price Advantage: Our price is competitive because we process valve parts by ourselves.

We think “Customer satisfaction is our ultimate goal.” Depending on our advanced technology, complete quality control and good reputation, we will offer more high-quality valve products.