The double eccentric butterfly valve is named after its two eccentric structures. So what is the double eccentric structure like?

The so-called double eccentric, the first eccentric refers to the valve shaft being off the center of the sealing surface, which means the stem is behind the valve plate face. This eccentricity makes the contact surface of both the valve plate and the valve seat a sealing surface, which fundamentally overcomes the inherent deficiencies that exist in concentric butterfly valves, thus eliminating the possibility of internal leakage at the upper and lower intersection between the valve shaft and valve seat.

Another eccentricity refers to the valve body center and stem axis left and right offset, that is, the stem separates the butterfly plate into two parts, one more and one less. This eccentricity can make the butterfly plate in the opening and closing process can be quickly detached or close to the valve seat, reduce the friction between the valve plate and the sealed valve seat, reduce wear and tear, reduce the opening and closing torque, and extend the service life of the valve seat.

How Double Eccentric Butterfly Valves Seal?

The outer circumference of the valve plate and the sealed seat of the double eccentric butterfly valve are machined into a hemispherical surface, and the outer spherical surface of the valve plate squeezes the inner spherical surface of the sealed seat to produce elastic deformation to achieve a closed state. The seal of the double eccentric butterfly valve belongs to the position sealing structure, which means the sealing surface of the valve plate and the valve seat is in line contact, and the sealing ring is usually made of rubber or PTFE. So it is not resistant to high pressure, and the application in the high-pressure system will lead to leakage.

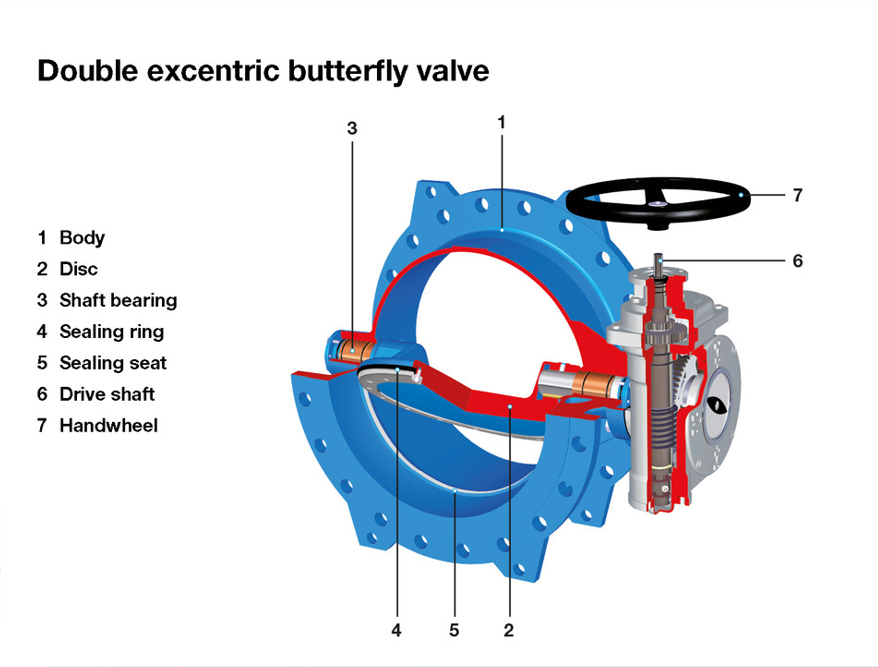

What Is The Main Part of Double Eccentric Butterfly Valve?

From The Picture Above, We Can Clearly See That The Main Parts Of The Double Eccentric Butterfly Valve Contain The Following Seven Items:

Body: The main housing of the valve, usually made of cast iron, ductile iron, or stainless steel, is designed to house the internal components of the valve.

Disc: The central component of a valve that rotates within the valve body to control the flow of fluid. The disc is usually made of cast iron, cast steel or bronze and has a flat or curved shape to match the shape of the valve body.

Shaft Bearings: shaft bearings are located in the valve body and support the shaft, allowing it to rotate smoothly and minimizing friction.

Sealing Ring: the rubber sealing ring is fixed to the valve plate by a pressure plate and stainless steel screws, and the valve sealing ratio is adjusted by adjusting the screws.

Sealing Seat: is part of the valve that seals the disc and avoids fluid leakage through the valve when it is closed

Drive shaft: connects the actuator to the valve flap and transmits the force that moves the valve flap to the desired position.

Actuator: controls the position of the disc within the valve body. And usually mounted on top of the valve body.

Picture Source: Hawle

The following video gives a more visual and detailed view of the design and feature of the double eccentric butterfly valve.

Advantages And Disadvantages Of Double Eccentric Butterfly Valve

Advantages:

1 Reasonable design, compact structure, easy to install and disassemble, flexible operation, labor-saving, convenient, and easy maintenance.

2 The eccentric structure reduces the friction of the sealing ring and extends the service life of the valve.

3 Completely sealed, zero leakage. Can be used in high vacuum condition

4 Change the material of the valve plate seal, butterfly plate, shaft, etc., which can be applied to a variety of media and different temperatures

5 Frame structure, high strength, large overflow area, small flow resistance

Disadvantages:

Because the sealing is a position sealing structure, the sealing surface of the butterfly plate and the valve seat are in line contact, and the sealing is produced by the elastic deformation caused by the butterfly plate pressing the valve seat, so it demands a high closing position and has a low capacity for high pressure and high temperature.

The Application Range of Double Offset Butterfly Valve:

- Water treatment and distribution systems

- Mining industry

- Shipbuilding and drilling facilities

- Chemical and petrochemical plants

- Food and chemical enterprises

- Oil and gas processes

- Fire extinguishing system

- HVAC systems

- Non-aggressive liquids and gases (natural gas, CO-gas, petroleum products, etc.)

Data sheet of Double Eccentric Butterfly Valve

|

TYPE: |

Double eccentric, Wafer, Lug, Double flange, Welded |

|

SIZE & CONNECTIONS: |

DN100 to Dn2600 |

|

MEDIUM: |

Air, Inert Gas, Oil, Seawater, Wastewater, Water, Steam |

|

MATERIALS: |

Cast Iron / Ductile Iron/ Carbon Steel / Stainless |

|

PRESSURE RATING: |

PN10-PN40, Class 125/150 |

|

TEMPERATURE: |

-10°C to 180°C |

Material of Parts

|

PART NAME |

Material |

|

BODY |

Ductile Iron, Carbon Steel, Stainless Steel, etc. |

|

BODY SEAT |

Stainless steel with welding |

|

DISC |

Ductile Iron, Carbon Steel, Stainless Steel, Alum-Bronze, etc. |

|

DISC SEAT |

EPDN;NBR;VITON |

|

SHAFT / STEM |

SS431/SS420/SS410/SS304/SS316 |

|

TAPER PINS |

SS416/SS316 |

|

BUSHING |

BRASS/PTFE |

|

O-RING |

NBR/EPDM/VITON /PTFE |

|

KEY |

STEEL |