1. What Is A Gate Valve?

A gate valve is a valve used to OPEN and SHUT-OFF the flow of fluid in a pipeline. It opens or closes the valve by lifting the gate to allow or restrict the flow of fluid. It should be emphasized that the gate valve cannot be used for flow regulation, but is only suitable for applications requiring full flow or complete closure.

Gate Valve Standard: GB/DIN/API/ASME/GOST.

GB standard:

| Design | Face to Face | Flange | Test |

| GB/T12234 | GB/T12221 | JB/T79 | JB/T9092 |

DIN standard:

| Design | Face to Face | Flange | Test |

| DIN3352 | DIN3202 F4/F5 | EN1092 | EN1266.1 |

API standard:

| Design | Face to Face | Flange | Test |

| API 600 | ASME B16.10 | ASME B16.5 | API 598 |

GOST standard:

| Design | Face to Face | Flange | Test |

| GOST 5763-02 | GOST 3706-93. | GOST 33259-2015 | GOST 33257-15 |

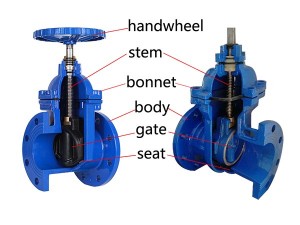

2.Gate Valve Structure

Gate valves usually consist of several key components:

1)Valve body: The most important component of the gate valve. The material is usually made of ductile iron, WCB, SS, etc.

2)Gate: control unit, which can be a rubber-coated plate or a pure metal plate.

3)Valve stem: used to lift the gate, made of F6A (forged ss 420), Inconel600.

4)Bonnet: the shell on the top of the valve body, which together with the valve body forms a complete gate valve shell.

5)Valve seat: the sealing surface where the gate plate contacts the valve body.

3. What are the Different Types of Gate Valves?

According to the valve stem structure type, it can be divided into non-rising stem gate valve and rising stem gate valve.

1)Non-rising stem gate valve: The top of the valve stem of the concealed stem gate valve does not extend with a hand wheel. The gate plate moves up or down along the valve stem to open or close the gate valve. Only the valve plate of the entire gate valve has displacement movement.

2)Rising stem gate valve (OS&Y gate valve): The top of the rising stem gate valve stem is exposed above the handwheel. When the gate valve is opened or closed, the valve stem and the gate plate are lifted or lowered together.

4. How Does A Gate Valve Work?

The operation of the gate valve is relatively simple and includes the following steps:

1)Open state: When the gate valve is in the open state, the gate plate is completely lifted and the fluid can flow smoothly through the channel of the valve body.

2)Closed state: When the valve needs to be closed, the gate is moved downward. It is pressed against the valve seat and in contact with the sealing surface of the valve body, preventing the passage of fluid.

5. What Is Gate Valve Used For?

Gate valves have a wide range of applications and can be used in various industries and environments, such as:

1)Water treatment: Soft seal gate valves are most commonly used for water and wastewater treatment.

2)Oil and natural gas industry: Hard seal gate valves are used in the oil and natural gas industry.

3)Chemical processing: Stainless steel gate valves are suitable for controlling the flow of chemicals and corrosive liquids in chemical processing.

4)HVAC Systems: Gate valves are used in heating, ventilation and air conditioning (HVAC) systems.

So, Can Gate Valves Be Used For Throttling?

As can be seen from the above, the answer is NO! The original purpose of the gate valve is to be fully open and fully closed. If it is forcibly used to adjust the flow, inaccurate flow, turbulence and other phenomena will occur, and it will easily cause cavitation and wear.

6. Advantages Of Gate Valve

1)Full flow: When fully open, the gate is level with the top of the pipe, providing unobstructed flow and minimal pressure drop.

2)0 Leakage: When the gate plate comes into contact with the valve seat, a tight seal is formed to prevent fluid from leaking through the valve. The sealing surfaces of the gate and valve seat are usually made of materials such as metal or elastic elastomer to achieve water sealing and air sealing with zero leakage.

3)Bidirectional sealing: Gate valves can provide bidirectional sealing, making them versatile in pipelines with reversible flow.

4)Easy maintenance: There is no need to dismantle the gate valve entirely. You only need to open the valve cover to fully expose the internal structure for maintenance.

7. Disadvantages Of Gate Valves

1)Compared with other valves with simple shapes (such as butterfly valves), the valve body uses a lot of materials and the cost is higher.

2)The maximum diameter of the gate valve should be smaller, generally DN≤1600. The butterfly valve can reach DN3000.

3)The gate valve takes a long time to open and close. If it needs to be opened quickly, it can be used with a pneumatic actuator.