What are the common problems and solutions for butterfly valves during use?

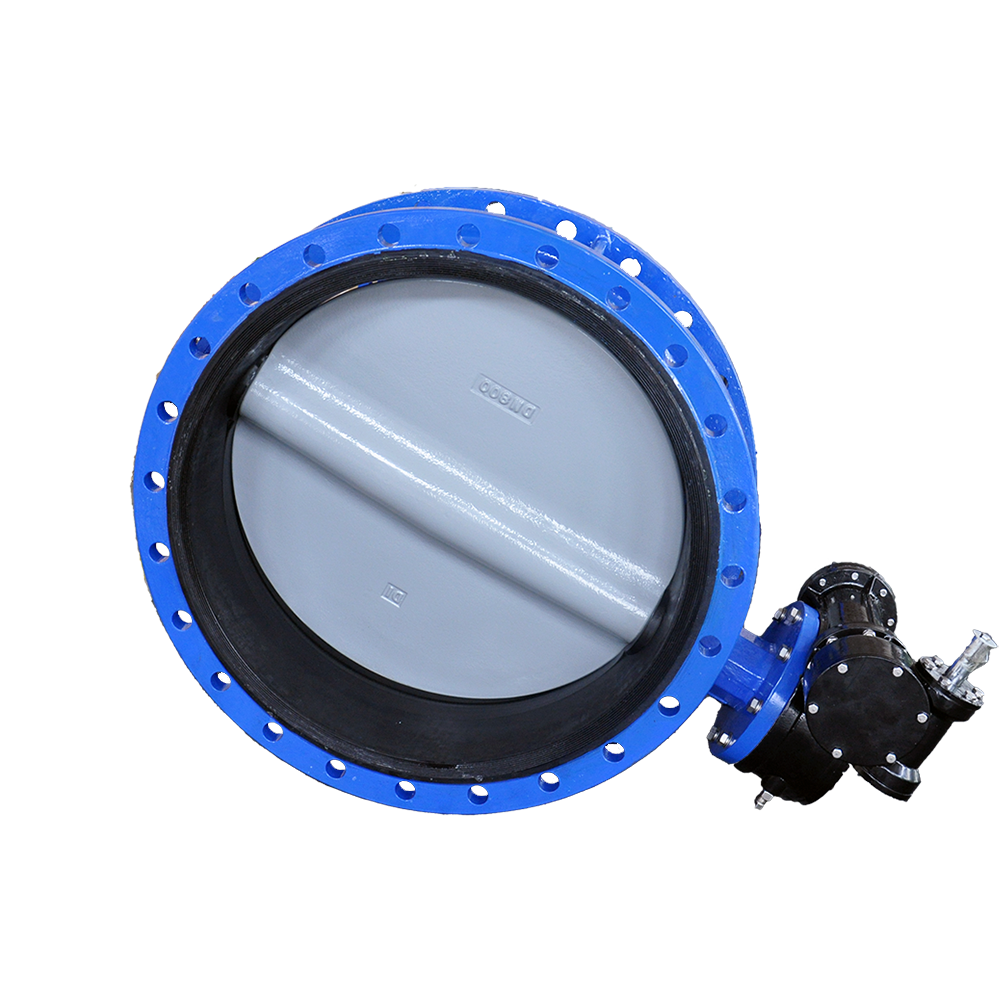

Butterfly valve because of its smaller size and simple structure, has become one of the most commonly used valves in the industry, more and more are applied to hydroelectric power, irrigation, building water supply and drainage, municipal engineering and other piping systems, used to cut off or mediate the flow of circulating media flow to use. Then the butterfly valve in the use of the problems that need attention and solutions to what, today we will be specific to understand.

Butterfly valve installation matters needing attention:

1.Before installation, please confirm the product performance and media flow arrow is consistent with the movement of the working conditions, and will be the valve cavity scrubbed clean, do not allow impurities in the sealing ring and butterfly plate attached to foreign objects, not cleaned before by no means allowed to close the butterfly plate, so as not to damage the sealing ring.

2.Disc plate installation supporting flange is recommended to use special flange butterfly valve.

3.Installed in the middle of the pipeline or the position of the two ends of the pipeline, the best position for the vertical installation, can not be installed upside down.

4. The use of the need to regulate the flow, there are manual, electric, pneumatic actuators for control.

5. Open and close more often butterfly valve, in about two months, need to open the worm gear box cover, check whether the butter is normal, should keep the right amount of butter.

6.Check whether the coupling parts are pressed, that is, to ensure the sealing of the packing, but also to ensure that the valve stem rotation is flexible.

7.Metal seal butterfly valve products are not suitable for installation at the end of the pipeline, such as must be installed at the end of the pipeline, you need to take the fitted outlet flange, to prevent the sealing ring accumulation of pressure, over position.

8.The valve stem installation and use of the response to regularly check the effectiveness of the valve, found faults in a timely manner.

Possible causes of failure: sealing surface leakage

1.Valve plate, sealing surface folder debris

2.Valve plate, sealing surface closing position coincide with incorrect

3.Outlet side configuration mounting flange bolts uneven force or loose bolts

4.Pressure test direction is not according to the requirements of the medium flow direction.

Elimination methods

1.Eliminate impurities, clean the inner cavity of the valve

2.Adjust the worm gear or electric, pneumatic actuator adjusting screws to achieve the correct position of the valve closure

3.Checking the fitted flange plane and bolt compression fastening, should be uniformly compressed

4.According to the arrow sealing direction for pressure

Valve two ends leakage failure causes

1.Both sides of the sealing gasket failure

2.Pipe flange tightness is not uniform or not compressed

3.Sealing ring or sealing ring in the gasket failure

Elimination method

1.Replace the sealing gasket

2.Pressure flange bolts (uniform force)

3.remove the valve pressure ring, replace the sealing ring and the failure of the gasket.

Butterfly valve can be divided into centre line butterfly valve and eccentric butterfly valve according to the structure form. According to the sealing form can be divided into soft seal type and hard seal type. Soft sealing type generally use rubber valve seat or rubber ring sealing, hard sealing type usually use metal ring sealing. According to the connection type, it can be divided into flange connection and wafer connection; according to the transmission mode, it can be divided into manual, electric, pneumatic and hydraulic. We can choose different actuators according to the working conditions.