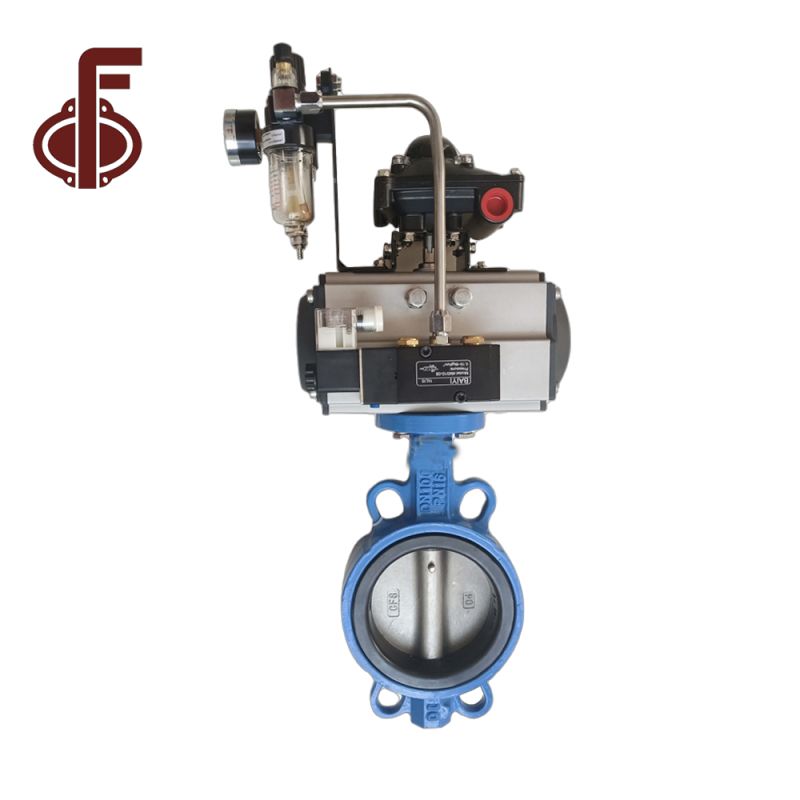

Super Purchasing For Ss 304 Butterfly Valve - PN16 CL150 Pressure Flange Type Butterfly Valves – Zhongfa

Super Purchasing For Ss 304 Butterfly Valve - PN16 CL150 Pressure Flange Type Butterfly Valves – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN4000 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

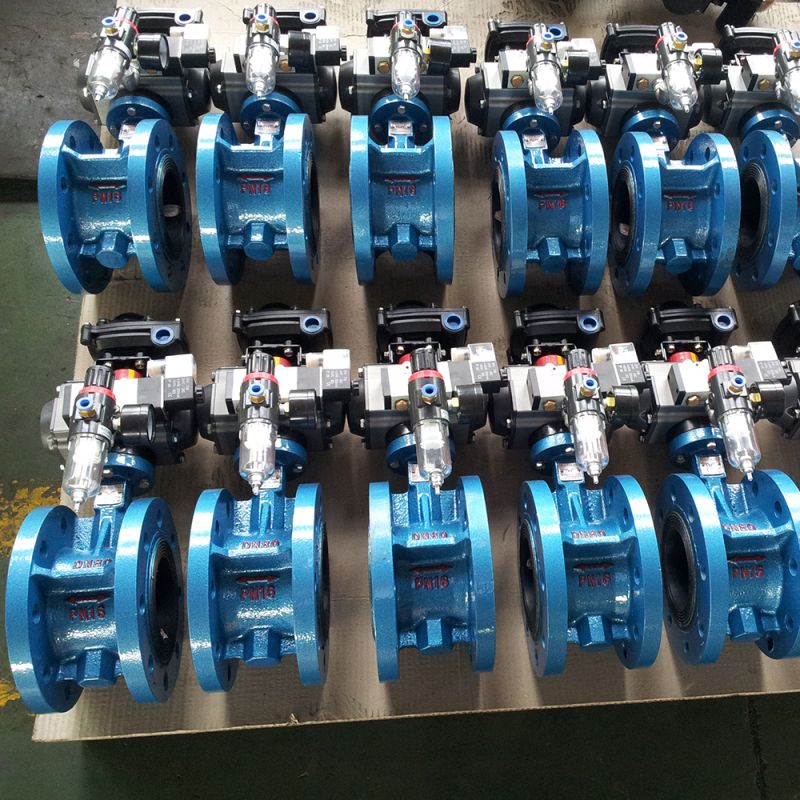

Product Display

Product Advantage

Our valve can be produced by different kinds of materials, it’s produced by international standard and national standard according to your requirement.

The valve body and inner parts are produced by CNC machine to guarantee the precision of the valve production. It’s an epoxy coating body with good looking appearance.

The valve body is made of QT450 or WCB, and its chemical composition and mechanical properties meet the requirements of national standards. Material reports are available.

There are rubber soft seals and stainless-steel hard seals to choose from. Parts such as valve plates can also be selected according to the working conditions.

The valve seat is welded by stainless steel, which is more wear-resistant and has a longer service life.

The valve shaft is supported by self-lubricating sleeve bearings, which can reduce the friction and torque generated during the transmission process of the valve shaft.

Butterfly valves are like ball valves but have more advantages. When actuated pneumatically, they open and close very quickly. Discs are lighter than balls, and the valve requires less structural support than a ball valve of comparable diameter. Butterfly valves are very precise, which gives them an advantage in industrial applications. They are very reliable and require very little maintenance.

Easy and fast opening/closing with less force. Has less fluid resistance and can be operated frequently

The structure is simple, the size is small, and the face-to-face size is short, which is suitable for large-diameter valves.

The sealing surface is generally made of rubber or plastic. Therefore, the butterfly valve has good sealing performance under low pressure.

Flanged rubber lined butterfly valves are widely used in the transportation of liquids and gases (including steam) in various industries

Pipelines, especially those used for severely corrosive media such as hydrofluoric acid, phosphoric acid, chlorine, strong alkalis, aqua regia and

4-level load elastic seal absolutely guarantees zero leakage inside and outside the valve.

This product is used for the water supply and drainage system in tap water, sewage, building, chemical etc. industries, usually used as an open-close equipment.

Butterfly valves are like ball valves but have more advantages. They are open and close very quickly when actuated pneumatically. The disc is lighter than a ball, and the valves require less structural support than a ball valve of comparable diameter. Butterfly valves are very precise, which makes them advantageous in industrial applications. They are quite reliable and require very little maintenance.

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Super Purchasing For Ss 304 Butterfly Valve - PN16 CL150 Pressure Flange Type Butterfly Valves – Zhongfa , The product will supply to all over the world, such as: Bulgaria, kazakhstan, Nepal, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, make sure you feel free to contact us. We hope to establish cooperative relationships with you in the near future.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!