If you are still hesitating whether to choose forged steel gate valves or cast steel (WCB) gate valves, please browse zfa valve factory to introduce the major differences between them.

1. Forging and casting are two different processing techniques.

Casting: The metal is heated and melted and then poured into a sand mold or mold. After cooling, it solidifies into an object. Air holes are easily produced in the middle of the product.

Forging: Mainly using methods such as hammering at high temperatures to make the metal into a workpiece with a certain shape and size in a plastic state, and change its physical properties.

2. Differences in performance between forged gate valves and WCB gate valves

During forging, the metal undergoes plastic deformation, which has the effect of refining the grains, so it is often used in the blank manufacturing of important parts. Casting has requirements on the materials to be processed. Generally, cast iron, aluminum, etc. have better casting properties. Casting does not have many advantages of forging, but it can manufacture parts with complex shapes, so it is often used in the blank manufacturing of support parts that do not require high mechanical properties.

2.1 Pressure

Due to differences in material properties, forged steel valves can withstand large impact forces, and their plasticity, toughness and other mechanical properties are higher than those of WCB valves. Therefore, it can be used in higher pressure working conditions. Commonly used pressure levels of forged steel valves are: PN100; PN160; PN250; PN320; PN400, 1000LB~4500LB. The commonly used nominal pressures of WCB valves are: PN16, PN25, PN40, 150LB~800LB.

2.2 Diameter Nominal

Because the forging process has high requirements on molds and equipment, the diameter of forged valves is usually below DN50.

2.3 Anti-leakage capability

Determined by the process itself, casting is prone to produce blowhole during processing. Therefore, compared with the forging process, the leakage prevention ability of cast valves is not as good as that of forged valves.

Therefore, in some industries with high leakage prevention requirements, such as gas, natural gas, petroleum, chemical and other industries, forged steel valves have been widely used.

2.4 Appearance

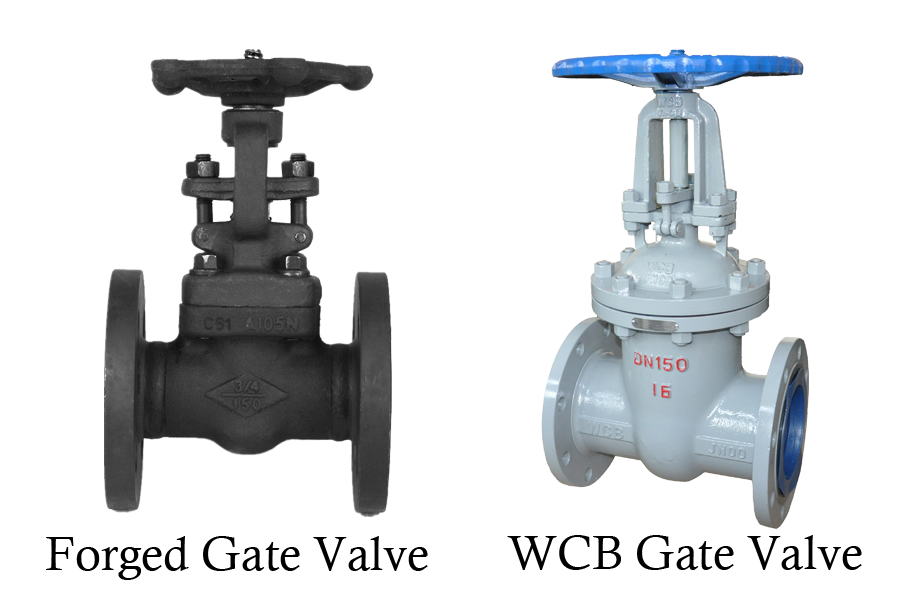

WCB valves and forged steel valves are easy to distinguish in appearance. Generally, WCB valves have a silver appearance, while forged steel valves have a black appearance.

3. Differences in application fields

The specific selection of WCB valves and forged steel valves depends on the working environment. It cannot be generalized as to which fields use forged steel valves and which fields use WCB valves. The selection should be based on the specific working environment. Generally speaking, WCB valves are not acid and alkali resistant and can only be used on ordinary pipelines, while forged steel valves can withstand high pressure and can be used in some factories with high temperatures, such as power plants and chemical plants. Class valve.

4. Price

Generally speaking, the price of forged steel valves is higher than that of WCB valves.

Post time: Nov-20-2023