Butterfly valves are indispensable components in various industrial applications. They have the function of shutting off fluids and regulating flow. So knowing the status of butterfly valves during operation—whether they are open or closed—is critical to effective use and maintenance.

Determining whether a butterfly valve is open or closed relies primarily on sight and indicators. When the actuator is not a handle, the way the valve plate moves up and down is different from other valves such as rising stem gate valves and globe valves (rising stem gate valves only need to observe the rising height of the valve stem to determine the position of the valve plate). Butterfly valves have unique The valve disc can rotate 0-90° in the valve body to change the flow of fluid.

Here is how to identify the position of the butterfly plate of a butterfly valve:

1. Visual inspection-toothed disc:

Small diameter butterfly valves, DN ≤ 250, can be equipped with handles and toothed discs. As the name suggests, the toothed disc generally has 10 scales, the first one is fully closed, and the last one is fully open.

Open position: When fully open, the valve disc is parallel to the flow direction, allowing the fluid channel to be unobstructed.

Closed position: In the closed state, the valve disc forms a vertical blockage on the fluid and stops the fluid movement.

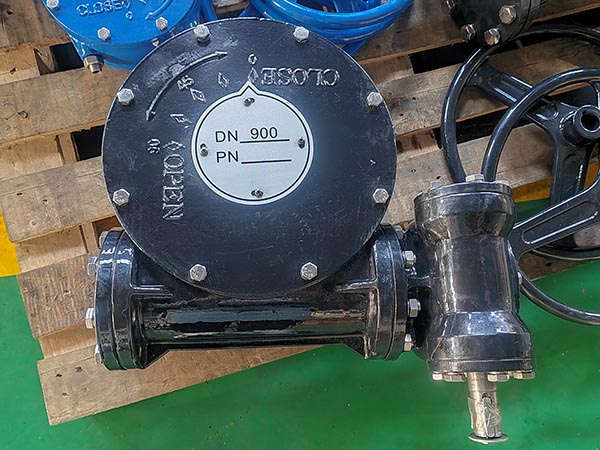

2. Position indicator:

Many butterfly valves are equipped with external indicators such as arrows or markings on the turbine head. These indicators align with specific markings that indicate the valve’s position.

3. Feedback signal:

In advanced systems, feedback signals from sensors or switches are integrated into the valve mechanism, providing real-time information about the valve’s status.

4. Remote monitoring:

Modern industrial installations may employ remote monitoring systems that allow operators to remotely check the status of butterfly valves and enhance control and supervision.

Ensuring proper butterfly valve positioning is critical to maintaining process integrity, preventing leaks and optimizing operating efficiency. Regular inspection and maintenance procedures should include verification of the condition of these valves to reduce risk and maintain system performance.

To sum up, identifying whether a butterfly valve is open or closed mainly relies on various visual and technical indicators. Understanding these clues is fundamental to effective valve management and industrial operations.

Post time: Feb-21-2024