Fire protection butterfly valves are very common in building fire-fighting systems.

They are mainly used to control water flow. They open and close quickly. They are compact and easy to install.

Compared with gate valves or globe valves, butterfly valves need much less operating force. This makes them especially suitable for large-diameter pipelines.

You can often find them on the main pipes of indoor fire hydrant systems, automatic sprinkler systems, fire pump outlets, zoned water supply systems, and outdoor fire mains.

They are everywhere in fire systems. Because of this, they are often taken for granted.

1. What Makes a Butterfly Valve “Fire Protection Grade”

1.1 Definition of a Fire Protection Butterfly Valve.

Fire protection butterfly valves are usually called fire signal butterfly valves or dedicated fire valves.

A fire protection butterfly valve is not defined by its appearance or name.

It refers to a butterfly valve that is suitable for use in fire-fighting systems. It is mainly used to control water flow in hydrant or sprinkler pipelines.

The key difference from a normal butterfly valve is this:

It can send real-time open or close signals to the fire control center.

In addition, a fire protection butterfly valve must work reliably under extreme fire system conditions, including:

*Long-term static pressure

*Sudden pressure rise when the fire pump starts

*Water hammer during valve operation or system switching

*Reliable operation in emergency situations

1.2 Why Are Butterfly Valves Used in Fire Systems?

90-degree operation for fast response

Low disc resistance and controlled pressure loss

More economical than gate valves for large sizes

2. Common Types and Materials of Fire Protection Butterfly Valves

Most fire protection butterfly valves are grooved type or flanged type.

They are equipped with position signals. The open and close status can be sent to the fire control room.

2.1 Connection Types

2.1.1 Grooved Butterfly Valve

Grooves are cut at the pipe ends and connected with couplings.

Installation is fast and welding is not required.

Grooves type butterfly valve is suitable for new buildings and site retrofits.

More than 80% of fire systems use this type.

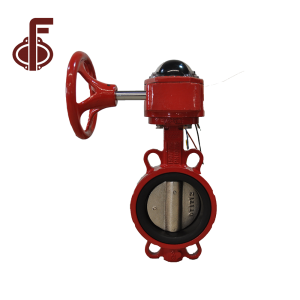

2.1.2 Wafer Butterfly Valve

The wafer type valve body has no flanges and is directly clamped between the flanges of two pipes.

It is the smallest and lightest, but requires precise alignment during installation.

2.1.3 Flanged Butterfly Valve

Both ends have flanges and are fixed with bolts.

Sealing is reliable and maintenance is convenient.

This type is often used for higher pressure or larger pipelines.

2.2 Sealing Types

2.2.1 Soft Seated Butterfly Valve

Rubber sealing is used. Tight shut-off performance.

Suitable for clean water at normal temperature.

2.2.2 Metal Seated Butterfly Valve

Metal-to-metal sealing. Better for higher pressure.

Suitable for water that may contain impurities.

For materials, the valve body is usually ductile iron with epoxy coating for corrosion protection.

The disc is ductile iron with nickel coating or stainless steel.

The stem is stainless steel.

Fire water often stays static for long periods. Corrosion risk is high.

These materials are chosen for long service life.

3. Main Pressure Ratings in Fire Protection Systems

3.1 Theoretical Spray Height Under Pressure

In most fire projects, PN16 is the default pressure rating.

According to the Chinese standard GB 50974 – Code for Design of Fire Water Supply and Hydrant Systems, the working pressure of indoor fire systems is usually between 1.0 MPa and 1.6 MPa.

For high-rise buildings or large spaces, pressure may be higher.

However, PN16 already covers most normal buildings.

Many people ask how high water can spray under this pressure.

Taking a fire hose nozzle as an example, under PN16 pressure, water can theoretically reach about 163 meters vertically.

This value is calculated using the formula:

h = P / (ρ × g)

Where:

P = 1.6 × 10⁶ Pa

ρ (water density) ≈ 1000 kg/m³

g ≈ 9.81 m/s²

Calculated result:

h ≈ 163 m

In real conditions, nozzle resistance, air friction, and pipe losses reduce the height.

The actual spray height is usually 140–150 meters.

This is enough for most buildings, such as high-rise residences and shopping malls.

3.2 Actual Spray Height in Engineering Practice

In fire systems, pressure is not theoretical.

It is directly related to building height.

After considering pipe losses, safety margins, and pressure fluctuations caused by pump start and stop, the following values are commonly accepted:

|

Condition |

Actual Height |

| Theoretical limit | 163 m |

| Ideal engineering condition | 110–130 m |

| Normal site condition | 80–100 m |

| Sprinkler / spray nozzle | 50–80 m |

Because of this, PN16 becomes the safest and most cost-effective choice.

3.3 Common Pressure Ratings in Fire Projects

Indoor fire hydrant systems → PN16

Automatic sprinkler systems → PN16

Outdoor fire mains → PN16 or higher

Fire pump discharge lines → PN20 / PN25 in some projects

If the pressure rating is lower than PN16,

the system may lack enough safety margin during emergency conditions.

Post time: Jan-23-2026