what is the difference between double eccentric and triple eccentric butterfly valve?

For industrial valves, both double eccentric butterfly valves and triple eccentric butterfly valves can be used in oil and gas, chemical and water treatment, but there can be a big difference between these two types of butterfly valves, so it is important to know the differences between these two types of valves in order to make the right choice.

In this article, we will look at the main differences between double offset butterfly valves and triple offset butterfly valves as well as their respective advantages and applications.

First, the design and construction are different.

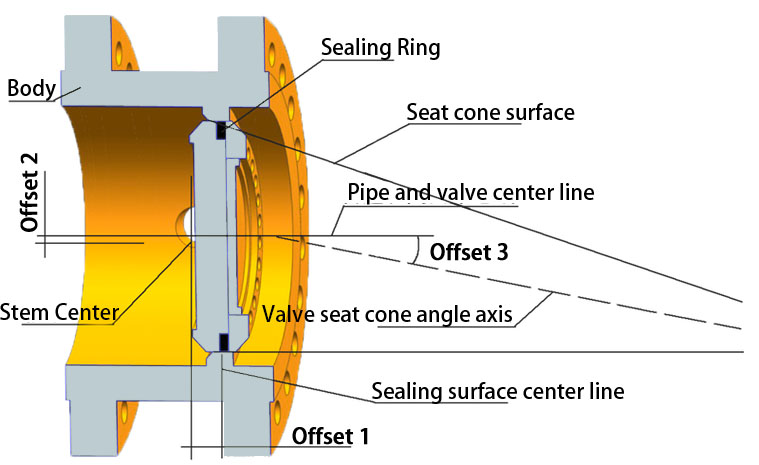

The disc of double eccentric butterfly valve is offset from the centerline of the valve body and shaft. This offset design helps friction and wear of the soft valve seat during opening and closing, thus prolonging service life and improving sealing. While the so-called triple eccentric butterfly valve has a third eccentric on top of the double eccentric, i.e., it forms a conical shape in the sealing surface, and the material of the sealing surface is usually metal sealing, which results in tighter sealing and less friction, making it ideal for high-pressure and high-temperature applications.

Second, the performance is different.

Triple eccentric butterfly valves offer several advantages over double eccentric designs. The triple eccentric design provides a air-tight seal, which means that leakage can be effectively prevented even under high pressure and high temperature conditions. So it is more suitable for critical applications that require tight shutoff. In addition, the triple eccentric butterfly valve’s cone cover design improves wear resistance so that maintenance intervals can be extended and maintenance costs reduced. These performance advantages make the triple eccentric butterfly valve the first choice for demanding applications in the oil and gas, petrochemical and power generation industries.

Finally, the cost of construction is not used.

The biggest advantage of double eccentric butterfly valve compared with triple eccentric butterfly valve is that the cost of construction is a little lower. If the working conditions do not require high temperature and high pressure triple eccentric butterfly valve, double eccentric butterfly valve is a more economical choice. This is because double eccentric butterfly valves are suitable for applications involving low to medium pressures and temperatures. Their reliable performance and cost-effectiveness make them a popular choice for a variety of industrial applications.

In conclusion, the choice between double and triple eccentric butterfly valves depends on the specific requirements of the medium and environment. Triple eccentric butterfly valves are suitable for conditions requiring high sealing as well as resistance to high pressures and temperatures, while double eccentric valves offer a cost-effective solution for less demanding applications.

Post time: Mar-15-2024