The assembly process of a butterfly valve is a simple yet complex process, which can be divided into several key steps. Only when each step is performed carefully can the butterfly valve operate normally. The following is a brief description of the wafer butterfly valve assembly process:

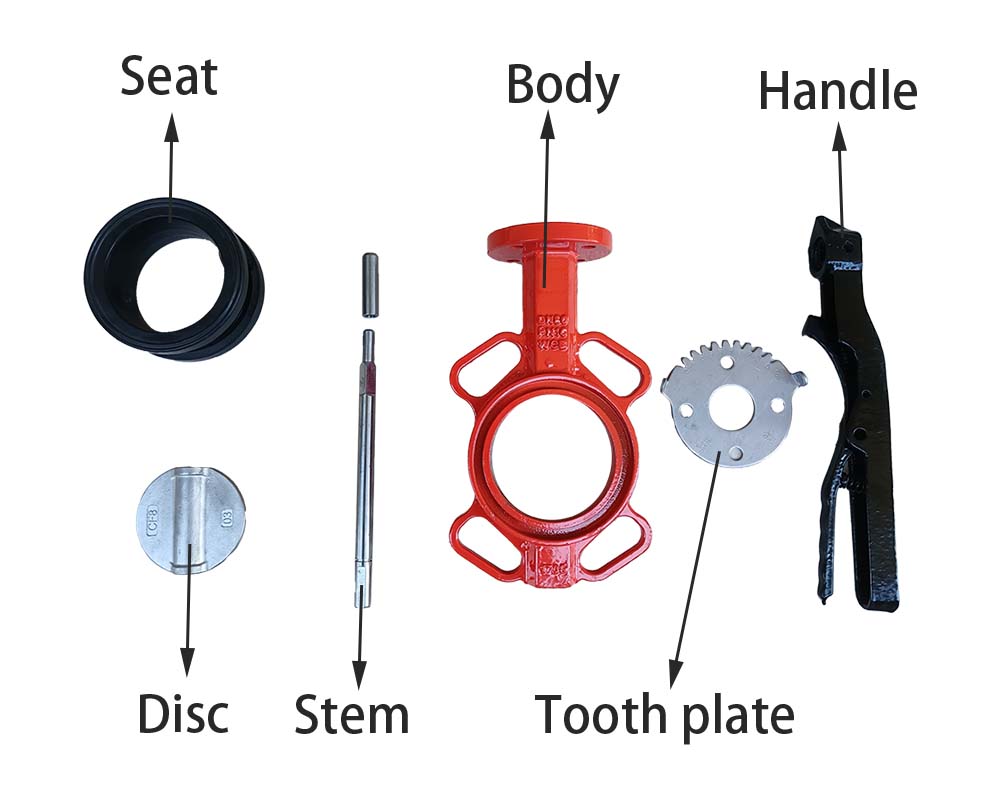

1. Check the valve parts list:

Before starting assembly, make sure you have all the required tools and materials. Check the parts list of the butterfly valve to make sure every part is clean and free of major flaws.

2. Place the sleeve, sealing ring, etc. into the valve body in advance.

3. Install the valve seat on the valve body:

3.1 Installation of the soft valve seat: After applying lubricating oil, bend the valve seat, align the valve seat hole with the valve body hole, and then fit the entire valve seat to the valve body, and tap the valve seat with a small mallet to embed it into the valve inside the body tank.

3.2 Installation of hard-backed valve seat: After applying lubricating oil, align the valve seat hole with the valve body hole, and then knock the valve seat completely into the valve body.

4. Install the valve plate

Press the valve plate into the valve seat ring and ensure that the valve plate hole and the valve seat hole are aligned so that the valve stem can be installed next.

5. Install the valve stem:

5.1 Double half-shaft valve stem installation: If there is an end cap, directly install the lower half of the valve shaft, and then install the other half of the valve shaft.

5.2 If there is no end cover, put the lower half of the valve shaft into the valve plate first, then install the valve plate, and then install the other half of the valve shaft.

Through-axis valve stem installation: Insert the valve stem into the valve body and connect it with the valve plate sleeve.

6. Install a circle and U shape buckle

Install these parts on the inside of the top flange to prevent relative movement of the valve stem.

7. Install the driver:

Install operating devices as needed, such as manual operating handles or electric actuators. Make sure the operating device is properly connected to the valve stem and can control the opening and closing of the valve.

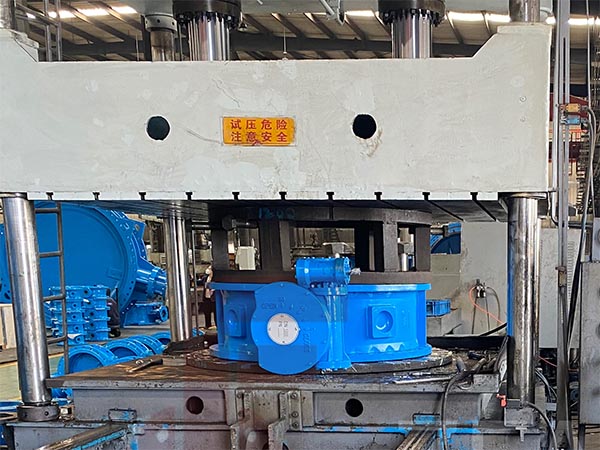

8. Test:

After assembly is complete, pressure and switch testing of the valve is performed to verify its performance and tightness. Ensure that the opening and closing torque of the valve is within a reasonable range and that there is no leakage on the sealing surface.

9. Final inspection

After assembly is complete, a final inspection of the entire butterfly valve is performed. Check that all fasteners are installed correctly and that all parts of the valve are in good condition. Make adjustments or corrections when necessary to ensure normal operation of the valve.

By carefully following the above steps, you can ensure that your butterfly valve will achieve the expected performance and reliability during installation. Zfa vave is a butterfly valve manufacturer from raw material valve parts machining to assembly, we get CE, API, ISO, EAC certificates etc.