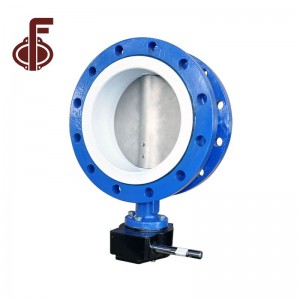

DN200 WCB Wafer Triple Offset Butterfly Valve with Worm Gear

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN50-DN600 |

| Pressure Rating | ASME 150LB-600LB, PN16-63 |

| Face to Face STD | API 609, ISO 5752 |

| Connection STD | ASME B16.5 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529) |

| Disc | Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529) |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | 2Cr13, STL |

| Packing | Flexible Graphite, Fluoroplastics |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

Product Advantage

Zero Leakage:

The triple offset configuration guarantees a bubble-tight closure, making it perfect for critical services where absolutely no leakage is permissible, such as in gas transmission or chemical manufacturing.

Minimal Friction and Wear:

Thanks to the offset disc arrangement, contact between the disc and seat is significantly reduced during operation, leading to less wear and an extended service lifespan.

Space-Saving and Lightweight:

The wafer-type construction occupies minimal space and weighs less compared to flanged or lugged designs, simplifying installation in confined areas.

Economical Choice:

Wafer-style butterfly valves typically offer a more affordable solution due to their streamlined design and reduced material consumption.

Exceptional Durability:

Constructed from WCB (wrought carbon steel), the valve exhibits superior mechanical robustness and withstands corrosive environments and elevated temperatures up to +427°C when paired with metal seating.

Broad Application Range:

These valves are highly adaptable, capable of handling diverse fluids such as water, oil, gas, steam, and chemicals across sectors including energy, petrochemical, and water management industries.

Reduced Operating Torque:

The triple offset mechanism minimizes the torque required for actuation, enabling the use of smaller and more cost-efficient actuators.

Fire-Resistant Construction:

Designed to comply with fire safety standards like API 607 or API 6FA, the valve is well-suited for environments with high fire risks, such as refineries and chemical plants.

High Performance Under Extreme Conditions:

Featuring metal-to-metal sealing, these valves are engineered to operate reliably under high temperature and high pressure, unlike conventional soft-seated valves.

Simplified Maintenance:

With less sealing surface degradation and robust overall construction, maintenance intervals are extended, and servicing requirements are reduced.