In the previous article, we talked about gate and globe valves, today we move on to butterfly valves and check valves, which are commonly used in water treatment.

1. Butterfly Valve.

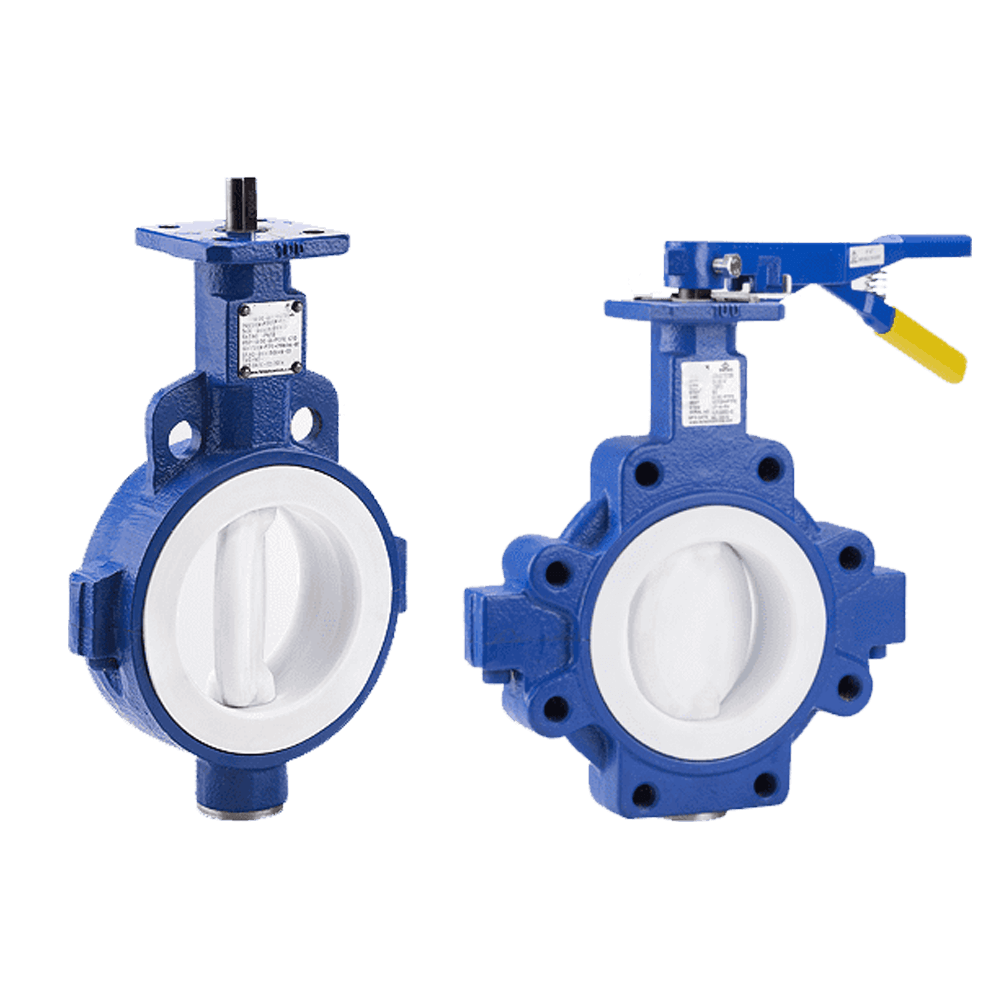

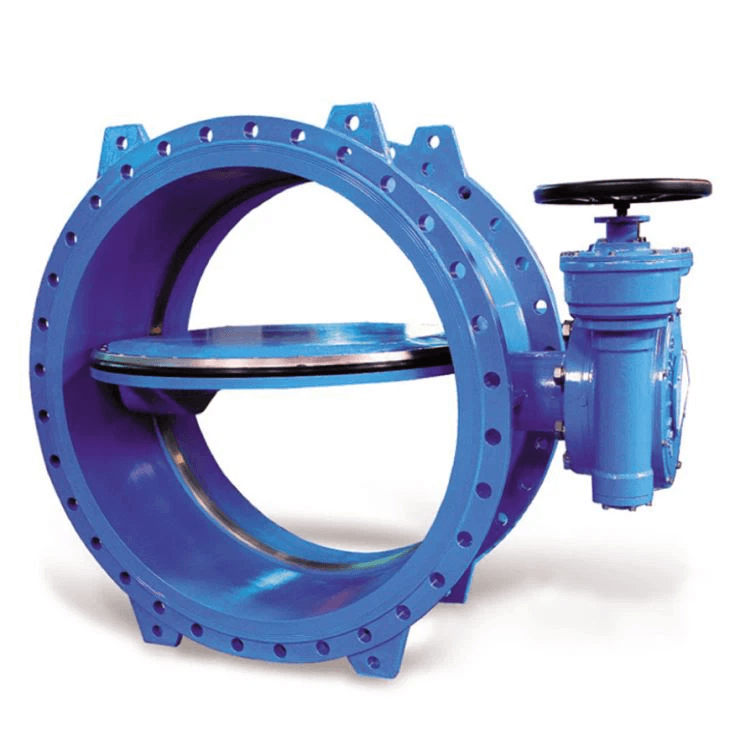

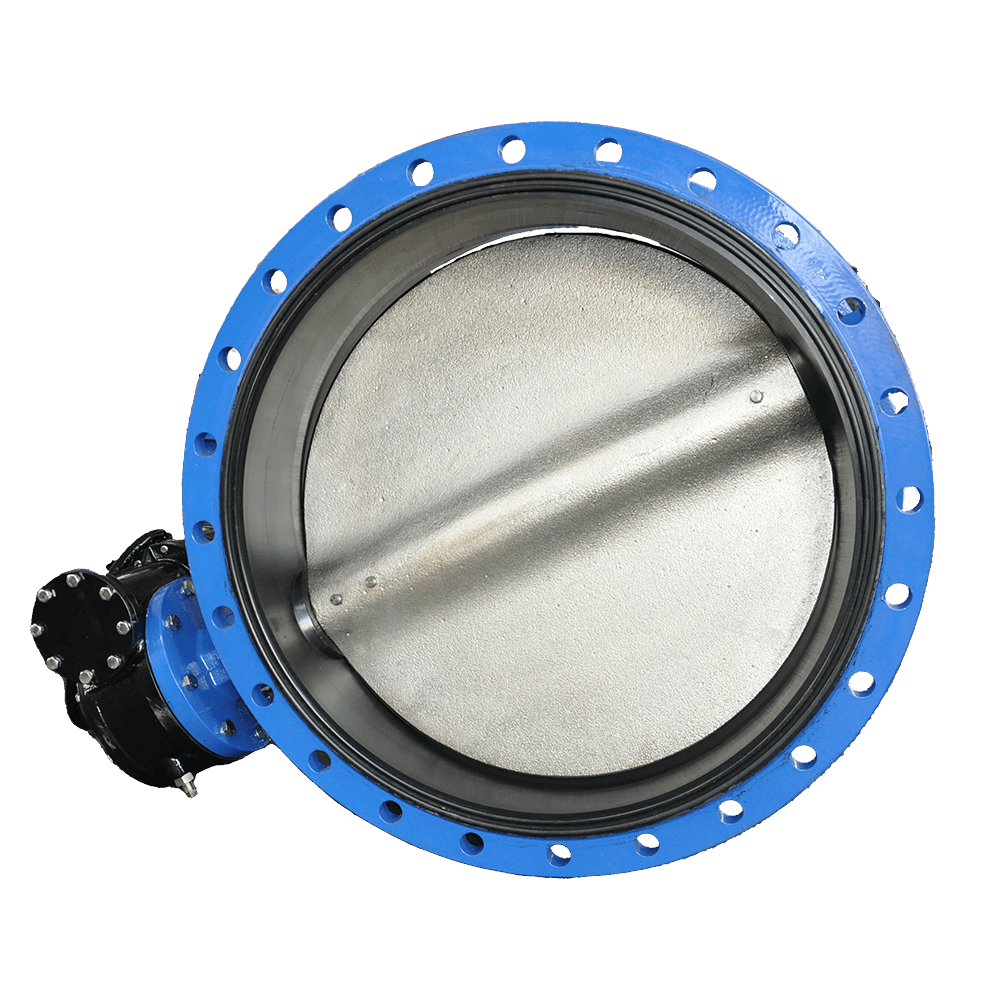

Butterfly valve is a rotary valve that uses a disc (also known as a butterfly plate) opening and closing member to rotate 90° or about 90° to open and close the channel. The movement of butterfly valve disc is wiping, so most butterfly valves can be used for media with suspended solid particles.

Commonly used butterfly valves include wafe and flanged butterfly valves. Wafer type butterfly valve is used to connect the valve between two pipe flanges with stud bolts, and flange type butterfly valve is with flange on the valve, and the flanges at both ends of the valve are connected to the pipe flange with bolts.

Features:

1. Small size, short length, simple structure and light weight.

2. Easy to operate, fast opening and closing, only need to rotate the disc 90° to open and close.

3. Good sealing and adjustment performance. Because rubber is used as the sealing ring, the compression and resilience are good (that is, it will not harden), so the sealing performance is good. . The valve flap can be opened between 15° and 70°, and can perform sensitive flow control.

4. Small operating torque and fluid resistance. According to measurements, the fluid resistance of butterfly valves is less than that of other types of valves except ball valves.

5. Due to the limitation of the sealing material, the operating pressure and operating temperature range of the butterfly valve are relatively small.

2.Check Valve

Uses and characteristics:

Check valve is a valve used to prevent the backflow of media in the pipeline, it opens when the medium flows downstream and closes automatically when the medium flows backward. Generally used in the pipeline does not allow the medium to flow in the opposite direction, in order to prevent the backflow of the medium damage to equipment and parts. When the pump stops running, do not cause the rotary pump reversal. In the pipeline, often check valves and closed-circuit valves used in series. This is due to the poor sealing of the check valve, when the media pressure is small, there will be a small portion of the media leakage, the need for closed-circuit valves to ensure the closure of the pipeline. Bottom valve is also a check valve, it must be submerged in the water, specifically installed in the pump can not be self-priming or no vacuum pumping water suction pipe front.

Water treatment valve common failures and measures

Valve in the pipeline operation for some time, there will be a variety of failures. First, the number of parts related to the composition of the valve, more parts are common failures. Secondly, with the valve design, manufacture, installation, operating conditions, maintenance advantages and disadvantages. General non-power-driven valve common failures are divided into four categories.

1.Transmission failure

Transmission device failure is often manifested as valve stem jamming, inflexible operation or the valve can not be operated. Reasons are: the valve is closed for a long time after the rust; installation and operation of improper damage to the stem threads or stem nut; gate is jammed in the valve body by foreign objects; gate is often half-open and half-closed state, by the water or other impacts lead to stem screws and stem nut wire misalignment, loosening, biting phenomenon; packing pressure is too tight, holding the stem; stem is topped off or by the closure of the parts jammed. Maintenance should be lubricated drive parts. With the help of a wrench, and gently tapping, you can eliminate the phenomenon of jamming, topping; stop the water repair or replacement of the valve.

2.Damaged valve body rupture

Valve body damaged rupture reasons: valve material corrosion resistance decline; pipe foundation settlement; pipe network pressure or temperature difference changes; water hammer; close the valve improper operation and so on. Should promptly remove the external causes and replace the same type of valve parts or valves.

3. Valve leakage

Valve leakage is manifested as: valve stem core leakage; gland leakage; flange gasket leakage. Common causes are: valve stem (valve shaft) wear, corrosion spalling, sealing surface pits, peeling phenomenon; seal aging, leakage; gland bolts, flange bolts loose. Maintenance to increase, replace the sealing medium; replace the new nut to readjust the position of the fastening bolt.

No matter what kind of failure if the usual repair, maintenance is not timely, may cause water waste, or worse, cause the whole system paralyzed. Therefore, the valve maintenance personnel must be on the causes of valve failure to do a good job, skilled and accurate regulation and operation of the valve, timely and decisive treatment of various emergency failures, to protect the normal operation of the water treatment network.

4.the valve opening and closing not good

Valve opening and closing bad performance for the valve is not open or closed, the valve can not be operated normally. Reasons are: valve stem corrosion; gate jammed or gate is closed for a long time in the state of rust; gate off; foreign objects stuck in the sealing surface or sealing groove; transmission parts wear, jamming. Encountering the above situation maintenance, lubrication transmission parts; repeated opening and closing the valve and hydrodynamic impact of foreign objects; replacement of the valve.