Classification and application of check valves

Check valve refers to the opening and closing parts for the round valve and rely on their own weight and media pressure to produce action to block the medium backflow of a valve. Check valve is an automatic valve, also known as check valve, one-way valve, non-return valve or isolation valve.

Flap movement is divided into lift check valve and swing check valve. Lift check valve and globe valve structure is similar, only the lack of valve stem to drive the valve flap. The medium from the inlet side (lower side) inflow, from the outlet side (upper side) outflow. When the inlet pressure is greater than the weight of the valve flap and its flow resistance and when the valve is open. Conversely, the valve is closed when the medium flows backwards. Swing check valve has a slant and can rotate around the axis of the valve flap, the working principle is similar to the lift check valve. Check valves are often used as the bottom valve of the pumping device, which can prevent the back flow of water. Check valves and globe valves used in combination, can play a safe isolation role. The disadvantages are high resistance and poor sealing when closed.

First, lift check valve contains vertical and horizontal two kinds.

The shape of the valve body of the lift check valve is the same as that of the globe valve, so it has greater fluid resistance. The valve flap slides along the vertical centre line of the valve body. When the medium is flowing, the valve flap is opened by the medium thrust, and when the medium stops flowing, the valve flap is landed on the valve seat by self hanging.

Vertical lift check valve. The medium inlet and outlet channel direction and the valve seat channel direction is the same, the flow resistance is smaller than the straight-through type. Vertical lift check valve is installed in vertical pipeline.through the lift check valve can only be installed in the horizontal pipeline. Restricted by the installation requirements, commonly used in small diameter occasions DN <50.

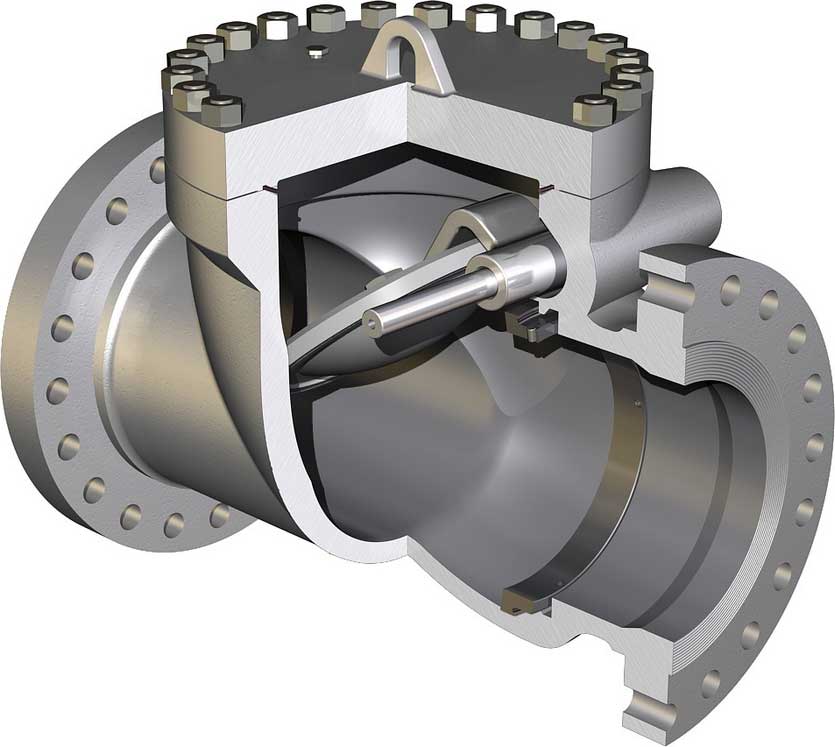

Second,The disc of the swing check valve is in a circular shape and rotates around the axis of the valve seat channel.

Due to the streamlined channel inside the valve, the flow resistance is smaller than that of the lift check valve. It is suitable for small and medium-sized, low-pressure, and large-diameter pipelines (low flow rate and large diameter situations where flow does not change frequently). The sealing performance is not as good as the lifting type.

Swing check valves are divided into three types: single disc, double disc, and multi disc. These three types are mainly classified according to the valve diameter, in order to prevent hydraulic shock when the medium stops flowing or flows backwards. Single disc swing check valves are generally suitable for medium caliber applications. When using a single disc swing check valve for large-diameter pipelines, it is best to use a slow closing check valve that can reduce water hammer pressure in order to reduce water hammer pressure. Double disc swing check valves are suitable for large and medium diameter pipelines. The double disc swing check valve with a small structure and light weight is a rapidly developing check valve; Multi disc swing check valves are suitable for large diameter pipelines.The installation position of the swing check valve is not limited, and it can be installed on horizontal, vertical, or inclined pipelines.

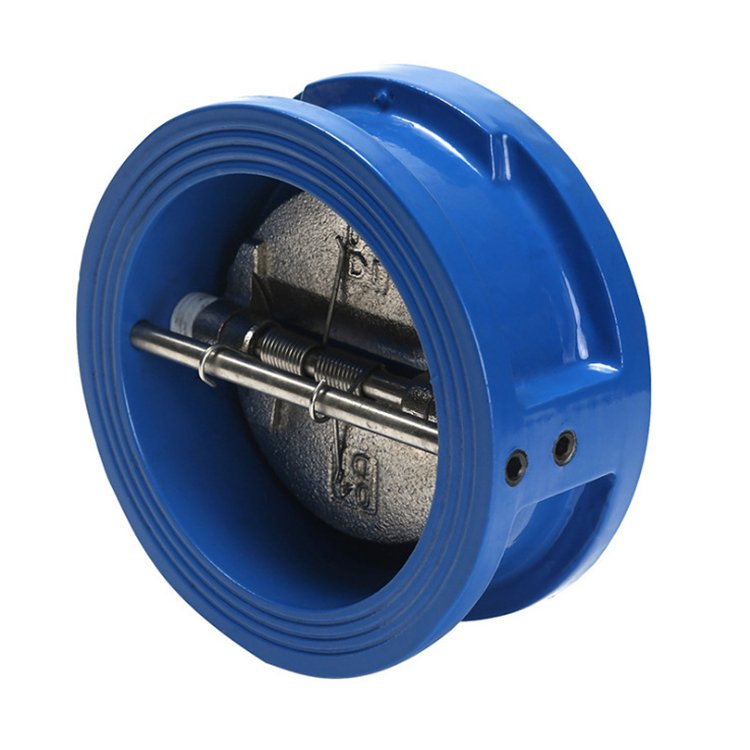

Third, butterfly check valve: straight-through type.

The structure of butterfly check valve is similar to butterfly valve. Its structure is simple, less flow resistance, water hammer pressure is also smaller. The valve flap rotates around the pin in the valve seat of the check valve. Disc type check valve has simple structure, can only be installed on the horizontal pipeline, the sealing is poor.

Fourth, the diaphragm check valve: there are a variety of structural forms, all using the diaphragm as the opening and closing parts.

Due to its water hammer performance, simple structure, low cost, in recent years the development of faster, the diaphragm check valve is widely used. But the use of diaphragm check valve temperature and pressure by the diaphragm material restrictions.Diaphragm check valve is suitable for easy to produce water impact on the pipeline, the diaphragm can be very good to eliminate the medium against the flow of water generated by the impact, it is generally used in low-pressure ambient temperature pipeline, especially suitable for water pipelines, the general working temperature of the medium in the -12 - 120 ℃ between the operating pressure of <1.6MPa, but the diaphragm check valve can be done to achieve a larger calibre, the maximum can be reached in the DN 2000mm or more! However, the diaphragm check valve can be of larger calibre, DN can reach 2000mm or more.