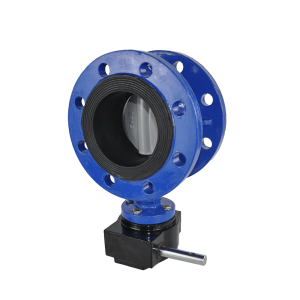

CF8M Disc Dovetail Seat Lug Butterfly Valve CL150

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN1200 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS lined with PTFE |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | EPDM |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

Product Advantage

Dovetail Seat: The dovetail seat design ensures that the seat material is firmly fixed in the valve body and prevents displacement during operation. This design improves sealing performance and durability, and also increases the convenience of seat replacement.

CF8M Disc: The CF8M is a cast AISI 316 with enhanced corrosion resistance, especially for chloride pitting. This makes it ideal for applications involving corrosive media such as seawater, chemicals or wastewater. The disc can be polished to improve its performance in abrasive or viscous fluids.

Lugged: Lugged butterfly valves have threaded ears on both sides of the valve body, which can be installed between two flanges using bolts. This design is easy to install and remove without interrupting the pipeline operation, and maintenance is also simpler.

Class 150: Refers to the rated pressure, which means that the valve can withstand up to 150 psi (or slightly higher, such as 200-230 psi, depending on the manufacturer and size). This is suitable for low-pressure to medium-pressure applications.

Flange connections are typically in accordance with standards such as ASME B16.1, ASME B16.5 or EN1092 PN10/16.