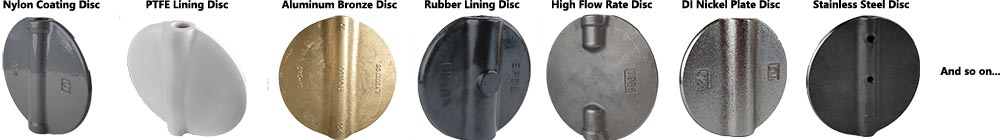

There’re many types of butterfly valve disc according to the usage of the butterfly valves, the most common sizes of butterfly valve for stocks are from DN50-DN600, so we’ll introduce the valve discs according to the sizes regularly used.

1. Nylon Coated Valve Disc

Nylon spraying is a common surface coating technology that sprays nylon particles in liquid form on the surface of the substrate and forms a strong and durable nylon film after solidification. Nylon spray coating has many uses and application scenarios, here are some of the common uses:

- Anti-corrosive protection: Nylon coating can be use as the surface protection of metal. Nylon has better anti-corrosive features, it can isolate metal with external flow medium, prolong life-span of the valve disc.

- Reduce friction: Nylon has better characteristic of friction reduction performance, it can easily reduce the friction between the valve seat and disc.

- Wear-resisting: Nylon has good performance of wear-resistant, it can reduce the scratch of the disc surface.

2. PTFE Lining Valve Disc

- Non-sticky: Surface of PTFE disc is very slippy and non-sticky, it can remarkably reduce the sticky from the medium obstacles.

- Corrosion resistance: PTFE has good anti-corrosive performance, it called King of plastic because of it’s extraordinary anti-corrosive features, it can resistant of many strong acid and alkali media.

- Chemical inertness: PTFE is inertness for most of the chemical substances. It can resist corrosion of most of the chemicals.

- Wearing-resistant: Although PTFE is a relatively soft material, but it has good wear-resistant performance compared to other plastic even metal. A disc with PTFE surface will have long time because of its feature.

3. Aluminum Bronze Valve Disc

Aluminum bronze is a copper alloy that typically contains aluminum, copper and other alloying elements such as manganese, iron and zinc. It has many advantages that make it widely used in various applications.

- Good corrosion resistance: Aluminum bronze has excellent corrosion resistance, especially in seawater and salt water environments. This makes it a commonly used material in marine and offshore engineering applications such as ship propellers, valves and pipes.

4.Nickel Plate Butterfly Valve Disc

- Anti-corrosive characteristics: Nickel plate can protect the surface of the ductile iron disc from corroded from working media.

- Hardness: With nickel plate, the surface of the DI disc can be hardener than before. It can help the disc resistance from working medium obstacles.

5.Rubber Lining Valve Disc

- Good sealing performance: A disc with rubber lining will have very good sealing performance compared to metal disc, will provide reliable sealing features. It helps the valve prevent leakage.

6.High Flow-rate Butterfly Valve Disc

- Special design of high flow-rate disc provide excellent flowing performance. According to its special shafe and accurate dimensions, it’ll lower the resistance and pressure drop of the working media, achieve high flow-rate.