Tianjin Zhongfa Valve is a professional manufacturer of butterfly valves. We have provided butterfly valve OEM services to customers in the United States, Russia, Canada, and Spain for 15 years, and Received unanimous praise from customers.

We can provide the following kinds of API609 butterfly valves:

According to the connection, we have double-flange butterfly valve, wafer butterfly valve and lug butterfly valve;

According to the material, we can provide ductile iron material, carbon steel material, stainless steel material, brass material, super duplex steel material;

According to the process, we can provide API609 butterfly valve with casting body and welding body.

According to the seat, we can provide soft seal, hard seal, multi-level seal API609 butterfly valve. Also embodied in there are concentric butterfly valve, eccentric butterfly valve, triple eccentric butterfly valve above.

Below are our four type API 609 Standard butterfly types

API 609 Wafer Type Butterfly Valve

API 609 Lug Type Butterfly Valve

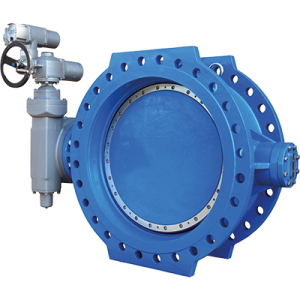

API 609 Flange Type Butterfly Valve

API 609 Eccentric Type Butterfly Valve

What is API609 Butterfly Valve?

API std 609 is the American Petroleum Institute's standard for butterfly valves in double-flange, lug and wafer connection forms. Certified and adopted by the American Petroleum Institute, API609-2016 is one of the versions, which determines the pressure class, rule size and flow path size of butterfly valves, and discusses the product structure design guidelines and testing standards.

The standard specifies the structure length of butterfly valve. there are two structure lengths of API609, A series and B series, A series has two kinds of connection of lug type and butt type, B series has three kinds of connection of lug type, butt type and double flange, among them, B class valve double flange butterfly valve, divided into long series double flange and short series double flange, the structure length of long series double flange and ASME B16.10 of flange type Gate valve consistent. The structure length listed in the short series is not consistent according to the pressure class, 150lb and 300lb are consistent with ISO 5752 basic series 13, EN 558-2, EN593, and 300lb and 600lb are consistent with ISO 5752 basic series 14, EN 558-2 and EN593. In addition, API609 also makes relevant regulations on valve details such as butterfly plate clearance, shaft and shaft seal, which can be found in API609-2016 and will not be repeated here.

How does a butterfly valve work?

The butterfly valve is a kind of valve that is opened and closed by rotating the stem and driving the disc plate at the same time. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, mainly by rotating the disc plate 90° to do flow control, when the disc plate reaches 90°, the valve is in the fully open state, and the angle of the disc plate can be changed to adjust the medium flow, which is generally installed in the diameter direction of the pipeline.

How to choose butterfly valve?

According to pressure rate: PN10, PN16, Class150, JIS 5K, JIS 10K, generally choose the middle line soft seal butterfly valve, if the pressure above, generally recommended to choose hard seal eccentric butterfly valve.

According to the media: non-corrosive, water and non-corrosive wastewater, choose the most common configuration of ball iron body ball iron plate, if the medium contains acid and alkali, generally choose fully lined or semi-lined butterfly valve, if the medium is sandy seawater, generally choose aluminum bronze, SS2205,SS2507 valve.

The operation mode of butterfly valve: handle, turbine, pneumatic, electric, hydraulic, according to the actual needs of the site to make a choice.

The application of butterfly valve: widely used in oil, natural gas, chemical, water treatment and other general industries, also used in thermal power plant cooling water system.