What is a butterfly valve?

A butterfly valve is a quarter-turn valve. It is used to regulate or isolate fluid flow in pipelines. Butterfly valve and because of its simple design and efficient performance and by all walks of life.

The origin of the name of butterfly valve: the valve flap is shaped like a butterfly and so named.

1. Structure

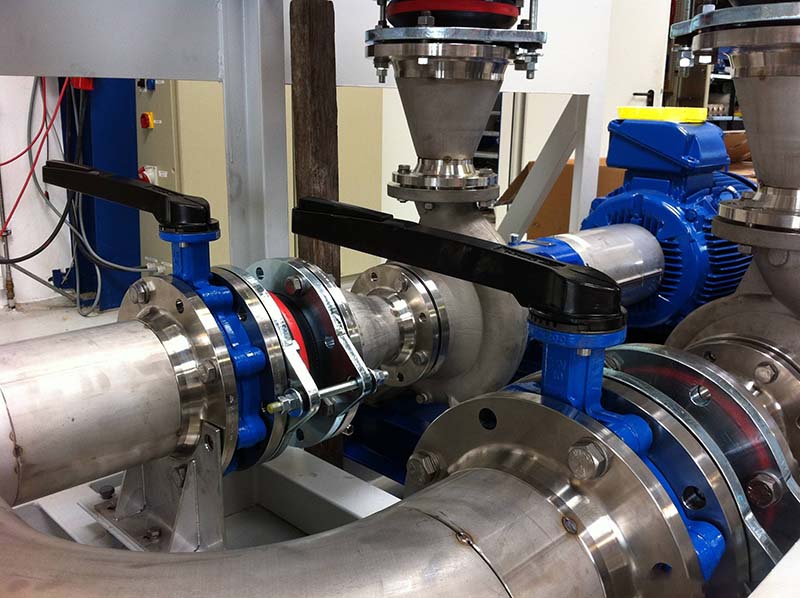

Butterfly valve consists of the following main components:

- Body: the housing that holds all internal parts and connects to the pipeline.

- Disc: a flat circular plate inside the valve body, which controls the flow of fluid by rotating.

- Stem: The shaft that connects the actuator to the valve flap and allows it to rotate.

- Seat: The sealing surface inside the valve body, where the flapper squeezes the seat to form a hermetic seal when closed to stop fluid flow.

- Actuator: Manual actuators such as handles, worm gears, but also electric and pneumatic.

These components combine to form a compact, lightweight valve that is easy to install and maintain.

---

2. Principle of operation

The operation of a butterfly valve is based on torque and hydrodynamics. The torque requirement varies depending on the pressure difference between the two sides of the butterfly valve and the position of the valve flap. Interestingly, the torque peaks at 70-80% valve opening due to the dynamic torque of the fluid. This characteristic requires precise actuator matching.

In addition, butterfly valves have an equal percentage flow characteristic curve, which means that small adjustments in the flap have a much greater effect on the flow rate at low valve openings than near full openings. This makes butterfly valves ideally suited for throttling control in specific scenarios, contrary to the common belief that they are only suitable for on/off use.

Butterfly valves are simple and efficient to operate:

- Open position: the valve flap is rotated parallel to the direction of the fluid, allowing the fluid to pass through almost unopposed.

- Closed position: the valve rotates perpendicular to the direction of the fluid, completely shutting off the fluid.

As a quarter-turn valve, it switches between fully open and fully closed by rotating only 90 degrees, quickly and efficiently.

---

3. Advantages and disadvantages

3.1 Advantages of butterfly valves

- Compact and lightweight: Smaller and easier to install than other valves such as gate or globe valves.

- Economical and efficient: lower cost due to simpler construction and less material.

- Quick to operate: can be opened or closed with a quarter turn, ideal for quick response to demand.

- Low maintenance costs: fewer moving parts means less wear and tear and simpler maintenance.

3.2 Disadvantages of butterfly valves

- Restricted throttling: not suitable for precise flow control, especially at high pressures, as it can lead to turbulence and wear and tear.

- Risk of leakage: some designs may not seal as tightly as other types of valves and there is a risk of leakage.

- Pressure drop: even when open, the valve flap remains in the flow path, resulting in a slight reduction in pressure.

- - - - - - - - - - - - - - - - - - - - - - - -

4. Applications

Butterfly valves are widely used in many industries because of their ability to manage large amounts of fluid with minimal pressure loss, making them ideal for large pipelines.

Example:

- Water treatment: managing water flow in water treatment plants and distribution networks.

- HVAC systems: control airflow in heating, ventilation and air conditioning systems.

- Chemical processing: Can be used to handle a wide range of chemicals due to material compatibility.

- Food and Beverage: for hygienic processes thanks to easy cleaning.

- Oil and gas: regulates and isolates flow in pipelines and refineries.

---

In short, butterfly valves are a practical and cost-effective fluid control option, appreciated for their simplicity and versatility.