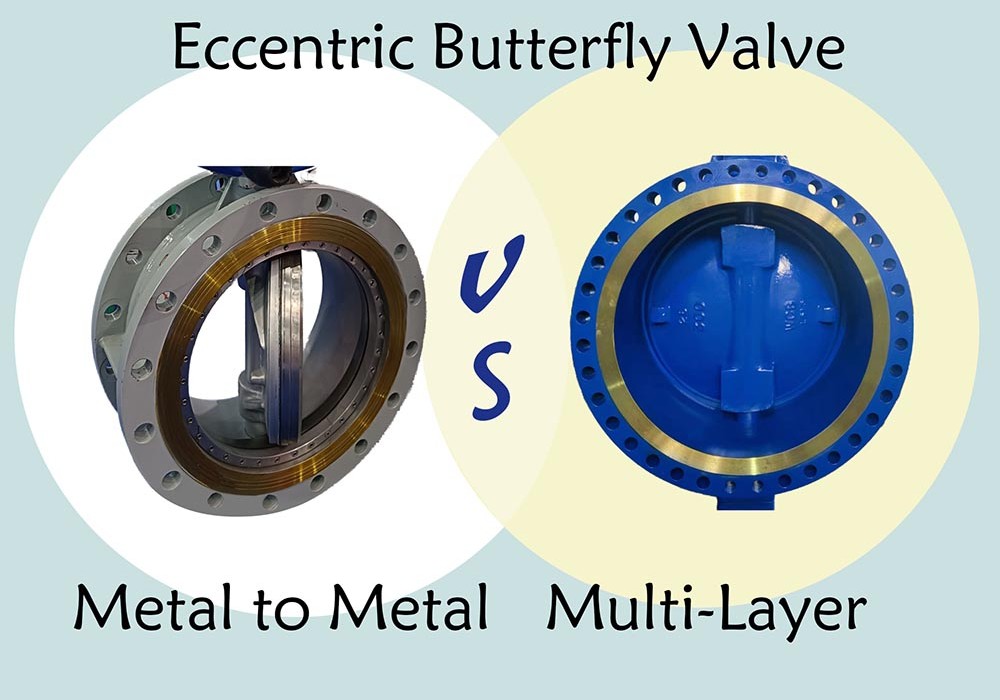

When customers purchase triple eccentric butterfly valves, they usually refer to two kind of structures, one is metal to metal seat and the other is multi-layer type; they have different structures and the prices are also quite different. Next, let’s discuss the difference between all-metal seat butterfly valves and multi-layer sealing butterfly valves.

1. Characteristics of metal to metal seat butterfly valves

The metal to metal seat butterfly valves is a butterfly valve with a simple sealing structure, consisting of a valve body, a valve plate, a valve shaft and a whole metal sealing ring. It has a compact structure and flexible opening and closing, so it is widely used in situations with low pressure, small flow, high temperature and tiny dust particles.

After the valve plate is opened, the valve seat of the valve body is close to the sealing ring. When the valve plate is closed directly against the fluid, the medium particles in the fluid are too big or too hard, which will cause friction on the valve seat or sealing ring, causing Damage to the valve seat or the sealing ring prevents complete sealing. This is also one of the shortcomings of metal to metal seat butterfly valve, because frequent switching will lead to increased friction and thus affect the service life.

2. Characteristics of multi-layer triple eccentric butterfly valve

Multi-layer butterfly valve is a butterfly valve with complex sealing structure. The sealing ring is usually composed of two or more layers, with multiple sealing layers in the middle. The valve body and valve plate of the multi-layer butterfly valve are assembled in layers. Each layer has an independent sealing structure, which can effectively reduce the risk of leakage. Because it is a multi-layer seal, even if there are particles in the medium during the closing process, as long as all the interlayers are not damaged, even if only one layer is left undamaged, the sealing performance will not be affected.

The multi layer butterfly valves usually used in high-pressure and large-flow situations, such as crude oil, natural gas, water and other industrial pipelines. The operating temperature is between -29 degrees and 425 degrees. WCB material is the most cost-effective choice.

3. The difference between metal to metal butterfly valves and multi-layer butterfly valves

1) similarities of these two butterfly vales

Both metal to metal butterfly valve and multi-layer butterfly valve can achieve one-way sealing or two-way sealing performance. According to user needs, one or more sets of spare sealing rings can be replaced for easy replacement in case of improper use, and are designed to be movable two-way sealing forms. The advantage of this design is that the valve seat and sealing ring can be replaced online, and the equipment does not need to be offline for maintenance. At the same time, they all have the advantage of getting tighter and tighter.

2) differences between these two butterfly vales

The main difference lies in the structure and application scenarios.

① difference of structure

Multi-layer butterfly valve

· The structure of the multi-layer butterfly valve is a stack of metal sheets and graphite, which means that the sealing ring is usually composed of two or more layers, with multiple sealing layers in the middle. The valve body and valve plate of the multi-layer butterfly valve are assembled in layers, and each layer has an independent sealing structure.

· The sealing pair of the all-metal two-way sealing butterfly valve, that is, the sealing ring and the valve seat, are made of all-metal forging. The sealing ring can be surfacing or spray welded with various wear-resistant and temperature-resistant alloys.

All metal seat butterfly valve

② Application

The Metal to metal butterfly valve is suitable for low pressure, small flow, and high temperature situations; the multi-layer butterfly valve has a more complete multi-layer sealing structure, which can effectively reduce the risk of leakage.

4. Metal to metal sealing performance of butterfly valves and multi-layer butterfly valves

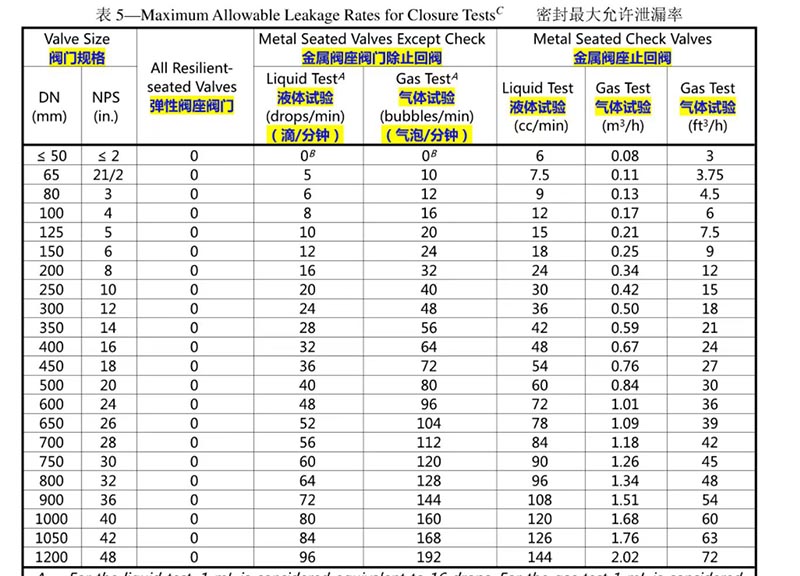

According to the API598 standard, a butterfly valve with a hard metal contact can have a leakage rate, but a butterfly valve with multi-layer sealing rings can achieve 0 sealing and has superior sealing performance.

5. Materials of all-metal sealing butterfly valves and multi-layer sealing butterfly valves

· Full metal seal: The valve seat usually has Stellite, the body material is WCB, SS304, SS316, SS2205, SS2507, and the valve plate sealing ring can be selected according to the material of the valve plate;

· Multi-layer sealing ring: Valve seat material: Stellite, or body material, valve plate sealing ring usually uses RPTFE/PTFE+metal, graphite+metal;

In general, both head-on butterfly valves and multi-level butterfly valves have their applicable scenarios, and users can choose the appropriate butterfly valve type according to the actual situation. When selecting a butterfly valve, parameters such as fluid pressure, temperature, flow rate and medium should be considered in order to select a suitable butterfly valve type and ensure the normal operation of the valve.

If the temperature is particularly high and there are no large particles, you can choose an all-metal hard-sealed butterfly valve.

If the temperature is not particularly high and the medium contains particles, choose a lower-priced multi-layer sealing butterfly valve.