"150 butterfly valve" typically involves two common parameters:

- DN150: Nominal diameter 150mm (equivalent to 6 inches in NPS).

- 150lb / 150 / Class 150: Pressure rating ANSI/ASME Class 150 (approximately 150 psi, common in American standard systems, equivalent to PN20 in China/Germany).

1. DN150 / 6" Butterfly Valve Dimensions

Butterfly valve types include Wafer, Lug, and Double Flanged. The following data summarizes key parameters based on standards such as ASME B16.5.

1.1 Wafer/Lug Type (Clip-on/Lug type, common short connection, conforms to ISO 5752):

- Face-to-Face Length: 55–57 mm

- Overall Height (bare shaft without actuator): 320–400 mm (concentric/high performance)

- Shaft size: ≈ 14*14mm

1.2 Double Flanged Type (Double Flanged connection, conforms to ISO 5752):

- Face-to-Face Length: Approx. 140mm/210mm

- Overall Height (bare shaft without actuator): 410 mm/589mm (concentric/double) 2. ASME B16.5 Class 150 Flange Basic Parameters (Applicable to NPS 6" / DN150)

This is the standard for butterfly valve flange connections (Wafer/Lug type requires a matching pipe flange, Double Flanged type comes with a flange).

|

Parameter |

Value (inches) |

Value (mm approx.) |

Notes |

| Flange Outside Diameter (OD) | 11.00 | 279.4 | |

| Bolt Circle Diameter | 9.50 | 241.3 | |

| Number of Bolts | 8 | – | |

| Bolt Size | 3/4" | M20 equivalent | UNC 3/4"-10 threads |

| Bolt Hole Diameter | 0.88 | 22.2 | |

| Raised Face Diameter | 8.50 | 215.9 | Typical for RF flanges |

| Flange Thickness (min) | 1.00 | 25.4 | Including raised face |

3. 150 Flange Bolt Chart & Torque

3.1 Class 150 NPS 6" Bolt Specifications:

- Number of Bolts: 8

- Bolt Diameter: 3/4"

- Recommended Stud Bolt Length (1/16" RF): Approx. 4 inches (102 (mm)

Recommended flange bolt torque for butterfly valve installation (after lubrication, cross-tightening):

|

Valve Size |

Bolt Size |

Min Torque (ft-lb) |

Max Torque (ft-lb) |

| 5"–8" | 3/4" | 30–40 | 100–120 |

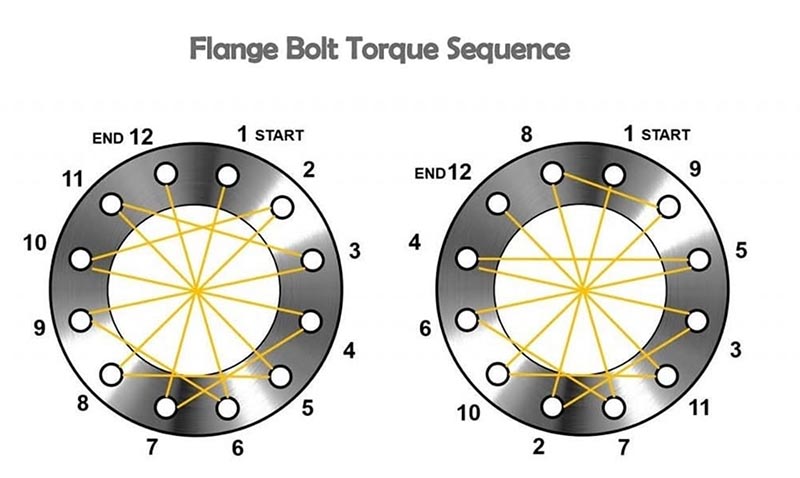

3.2 Tightening Steps (Cross-Tightening):

a. First Round: 30% Torque

b. Second Round: 60% Torque

c. Third Round: 100% Torque

d. Final Round: Check clockwise/counterclockwise