1. What is a pneumatic butterfly valve?

A pneumatic butterfly valve is a quarter-turn valve used to regulate or isolate fluid flow in a pipeline. It consists of a circular disc (often called a "disc") mounted on a stem, which rotates inside the valve body. "Pneumatic" refers to the actuation mechanism, which uses compressed air to operate the valve, enabling remote or automated control.

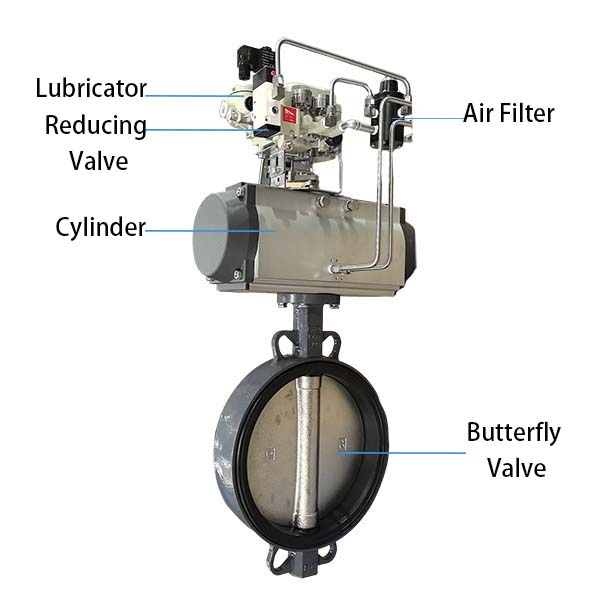

A pneumatic butterfly valve can be divided into two key components: the pneumatic actuator and the butterfly valve.

· Butterfly valve body: Consists of the valve body, disc (disc), stem, and seat. The disc rotates around the stem to open and close the valve.

· Pneumatic actuator: Utilizes compressed air as a power source, driving a piston or vane to produce linear or rotary motion.

Key Components

*Butterfly Valve:

- Valve Body: The housing that houses the disc and connects to the pipe.

- Disc (disc): A flat or slightly raised plate that controls flow. When held parallel to the flow direction, the valve opens; when held perpendicular, it closes.

- Stem: The rod connected to the disc that transmits the rotational force from the actuator.

- Seals and seats: Ensure a tight shutoff and prevent leakage.

*Actuator

- Pneumatic actuator: Typically a piston or diaphragm type, it converts air pressure into mechanical motion. It can be double-acting (air pressure for both opening and closing) or single-acting (air for one direction, spring for return).

2. Operating Principle

The operation of a pneumatic butterfly valve is essentially a chained process of "compressed air actuation → actuator actuation → disc rotation to control flow." Simply put, pneumatic energy (compressed air) is converted into rotary mechanical motion to position the disc.

2.1. Actuation Process:

- Compressed air from an external source (such as a compressor or control system) is supplied to the pneumatic actuator.

- In a double-acting actuator, air enters one port to rotate the valve stem clockwise (i.e., to open the valve), and enters the other port to rotate it counterclockwise. This generates linear motion in the piston or diaphragm, which is converted into a 90-degree rotation by a rack-and-pinion or Scotch-yoke mechanism.

- In a single-acting actuator, air pressure pushes the piston against the spring to open the valve, and releasing the air allows the spring to automatically close it (fail-safe design).

2.2. Valve Operation:

- As the actuator rotates the valve stem, the disc rotates inside the valve body.

- Open Position: The disc is parallel to the flow direction, minimizing resistance and allowing full flow through the pipeline. - Closed position: The disc rotates 90 degrees, perpendicular to the flow, blocking the passage and sealing against the seat.

- The intermediate position can throttle flow, although butterfly valves are more suitable for on-off service than for precise regulation due to their nonlinear flow characteristics.

2.3. Control and Feedback:

- The actuator is typically paired with a solenoid valve or positioner for precise control via electrical signals.

- A sensor may provide valve position feedback to ensure reliable operation in automated systems.

3. Single-Acting and Double-Acting

3.1 Double-Acting Actuator (No Spring Return)

The actuator has two opposing piston chambers. Compressed air is controlled by a solenoid valve, alternating between the "opening" and "closing" chambers:

When compressed air enters the "opening" chamber, it pushes the piston, causing the valve stem to rotate clockwise (or counterclockwise, depending on the design), which in turn rotates the disc to open the pipeline.

When compressed air enters the "closing" chamber, it pushes the piston in the opposite direction, causing the valve stem to rotate the disc counterclockwise, closing the pipeline. Features: When compressed air is lost, the disc remains in its current position ("fail-safe").

3.2 Single-Acting Actuator (with Spring Return)

The actuator has only one air inlet chamber, with a return spring on the other side:

When air is flowing: Compressed air enters the inlet chamber, overcoming the spring force to push the piston, causing the disc to rotate to the "open" or "closed" position;

When air is lost: The spring force is released, pushing the piston back, causing the disc to return to the preset "safety position" (usually "closed", but can also be designed to be "open").

Features: It has a "fail-safe" function and is suitable for use in applications requiring safety measures, such as those involving flammable, explosive, and toxic media.

4. Advantages

Pneumatic butterfly valves are suitable for fast operation, typically requiring only a quarter turn, making them suitable for industries such as water treatment, HVAC, and chemical processing.

- Fast response time due to pneumatic actuation.

- Low cost and simplified maintenance compared to electric or hydraulic alternatives.

- Compact and lightweight design.