A fully lined butterfly valve features a fully lined structure within the valve body. This design is specifically designed for corrosion-resistant applications.

“Fully lined” means that not only the disc is completely enclosed, but also the seat is completely enclosed, ensuring complete isolation between the media and the metal.

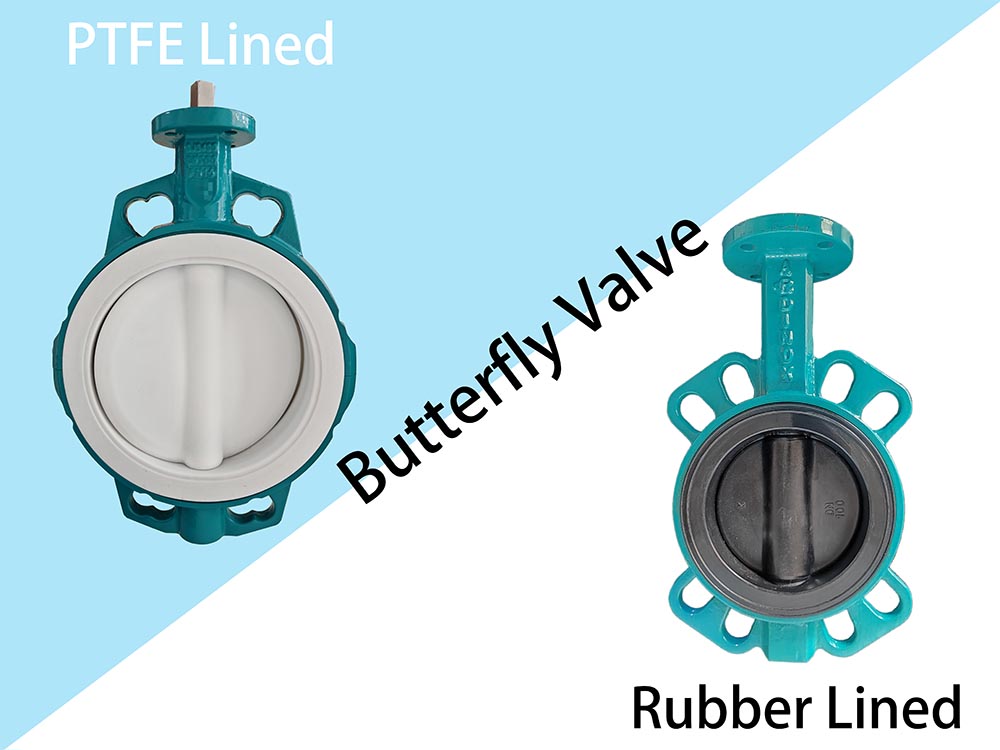

1. Two common lining materials

a. PTFE (polytetrafluoroethylene, perfluoroplastic) lining butterfly valve

b. Rubber lining butterfly valve

|

Material Type: |

Polytetrafluoroethylene (PTFE) lining |

Rubber lining (e.g., EPDM, Viton, NBR) |

|

Lining Process |

Molten PTFE/PFA is poured into the dovetail groove on the body/disc, achieving a seamless bond. | It is then directly vulcanized (heat-cured) onto the metal, forming a tight, integral seal. |

|

Core Features |

- Excellent corrosion resistance (resistant to nearly all acids, bases, and organic solvents)

- High temperature resistance (continuous operating temperature up to 180°C) - Low friction coefficient and non-stick properties, suitable for high-purity media

|

- Excellent elasticity and excellent sealing performance (easy to achieve zero leakage)

- Low cost and good wear resistance for non-corrosive media - Low temperature resistance (typically -20°C to 180°C, depending on the rubber type)

|

|

Applicable Media |

Strong acids (such as sulfuric acid and hydrochloric acid), strong bases, organic solvents, high-purity fluids | water, wastewater, weak acids and bases, slurries, and food-grade media |

|

Typical Applications |

Chemical Industry (acid and alkali transfer), Pharmaceutical Industry (high-purity material transfer) | Water Treatment (wastewater treatment, tap water), HVAC Systems, Food and Beverage Industry, Mining (slurry transfer) |

2. Detailed Process Steps for PTFE-lined Valve Discs

2.1 Metal Disc Preparation

a.. Cast or machine the metal disc core, ensuring the surface is clean and free of oil and contamination.

b.. Cut grooves (dovetail shape) on the core surface to provide anchor points for PTFE injection and prevent it from falling out.

2.2 PTFE Powder Molding and Preforming

a. Place a carefully calculated amount of PTFE powder (or premix) into the mold, insert the metal butterfly valve core, and then add the PTFE powder.

b. Gradually apply vacuum (exhaust) and pressure (compression or isostatic pressing) to form a green embryo. Isostatic molding: Immerse the mold in water and apply uniform pressure on all sides (water pressure conduction) to ensure a uniform and dense structure (porosity as low as <1%).

2.3 Sintering and Curing

a. Place the green embryo in an oven and sinter at 380°C for 5-24 hours (gradually increase the temperature to avoid cracks).

b. Slowly cool to room temperature to allow the PTFE to crystallize and fuse with the metal core, forming a seamless coating (thickness controlled to be 3-10mm, adjusted according to vacuum conditions).

2.4 Machining and Finishing:

Use a lathe or CNC machine to machine the inner and outer diameters to ensure the disc and seat fit perfectly (tolerances are tight, e.g., ±0.01mm).

2.5 Quality Inspection and Testing:

a. Thickness Measurement: Ensure a minimum lining of 3mm, or as customized.

b. Spark Test: 35,000 volts for tightness testing (no breakdown indicates acceptance).

c. Vacuum/Strength Test: Simulates operating conditions to check leaks and permeability (in accordance with EN 12266-1 or API 598).

d. Conductivity Test (optional): Surface resistance <10⁶Ω for explosion-proof applications.

3. Detailed Process Steps for EPDM-lined Discs

3.1 Metal Disc Preparation

a. Cast or machine the metal core to ensure a clean, rust-free surface.

b. Sand or chemically etch the surface (roughness Ra 3-6μm) to promote EPDM adhesion.

3.2 EPDM Compound Application and Preforming

Uncured EPDM compound (sheet or liquid) is placed in a mold, wrapping around the metal core. Using compression molding or pouring, evenly distribute the compound over the valve disc surface to form a green body. Maintain a thickness of 2-5 mm, ensuring coverage around the edges of the disc.

3.3 Curing

The green body is placed in an autoclave and heated with steam or hot air (150-180°C, pressure >700 psi, for 1-4 hours).

The curing process cross-links and cures the EPDM, chemically and mechanically bonding it to the metal core to form a seamless, one-piece lining. Increase the temperature slowly to avoid air bubbles or cracks.

3.4 Machining Finishing

After cooling, trim the inner and outer edges using a CNC lathe to ensure the disc and seat fit perfectly (tolerance ±0.05 mm). Remove excess rubber and inspect the edge profile (Ni-Cu coating is optional for improved wear resistance).

3.5 Quality Inspection and Testing

a. Thickness and Adhesion Testing: Ultrasonic thickness measurement (minimum 2mm); Tensile Testing (peel force >10 N/cm).

b. Performance Verification: Bubble Tight Seal Test (API 598 standard); Pressure/Vacuum Test (PN10-16, negative pressure resistance).

c. Chemical/Aging Test: Immersion in acid and alkaline media, checking expansion <5%; High-temperature aging (120°C, 72h).

4. Selection Guide

PTFE linings are suitable for highly corrosive media (such as acids, alkalis, and solvents), while EPDM linings are suitable for water-based, mild media (such as water and dilute acids). Prioritize chemical compatibility, temperature, pressure, and cost to optimize the application. Zhongfa Valve manufactures fully lined butterfly valves with wafer, flange, and lug options. Please contact us with any questions.

Post time: Oct-28-2025