1. What is a PTFE Fully Lined Butterfly Valve?

PTFE (polytetrafluoroethylene) fully lined butterfly valves are widely used in piping systems for highly corrosive media (such as strong acids, strong bases, and organic solvents) because both the valve body and disc are completely lined with PTFE, providing excellent corrosion resistance and sealing performance. The valve body structure is mainly divided into two types: two-piece (split body) and one-piece body. The two-piece structure is the mainstream design for PTFE fully lined butterfly valves, while the one-piece design is less common, mainly due to limitations in the lining process.

2. Similarities

Size: DN50-DN600. Unlike conventional butterfly valves with EPDM seats, the minimum size for PTFE seats is DN50.

Pressure: Limited by the PTFE material, especially the PTFE-lined disc, it is suitable for a maximum pressure of PN10 (PN16 requires special specifications).

Temperature: Operating temperature is -10 to 180 degrees Celsius. (RPTFE is usually -20 to 200 degrees Celsius)

3. Main Differences and Comparison

3.1 Structural Features

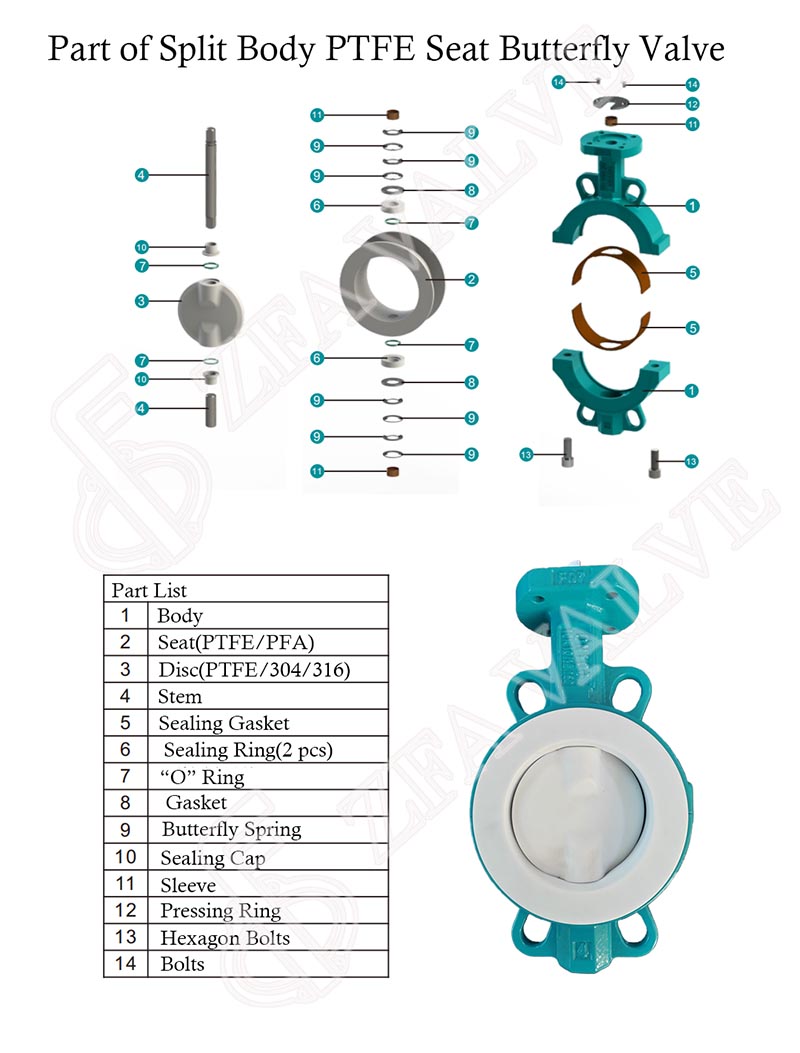

Two-piece Body (Split Body): The valve body consists of two halves (or two pieces) assembled and connected by bolts. The lining is formed on each half separately before assembly.

One-piece Body(Whole Body): The valve body is cast or machined as a single piece, and the lining requires injection molding or a special process for complete encapsulation.

3.2 Manufacturing Process

Split butterfly valve body: The valve body consists of upper and lower parts connected by bolts. The PTFE lining (including silicone rings) is usually formed separately before assembly. Therefore, the lining process for the two-piece body is simpler and does not require special molds or tools for assembly.

Whole butterfly valve body: The valve body is cast or machined as a single piece, without intermediate joint surfaces. The PTFE lining is integrated with the valve body through integral molding or sintering.

3.3 Sealing Performance

Two-piece (Split Body): Bidirectional zero leakage (bubble-tight), but the joint surface requires a good sealing design (such as O-rings or gaskets).

One-piece (whole Body): No joint surfaces, fewer potential leakage points, and higher sealing reliability.

3.4 Applicable Sizes

Two-piece (Split Body): Commonly available in DN50~DN600, and even larger sizes are easily achievable.

One-piece (Monoblock Body): Mostly limited to small diameters; larger sizes are difficult to manufacture.

3.5 Ease of Maintenance

Two-piece butterfly valve body: Excellent: Easy to disassemble, no special tools required, and the lining halves or butterfly disc can be replaced individually, making maintenance convenient.

One-piece butterfly valve body: Poor: Difficult to repair locally when the lining is damaged; usually requires replacing the entire valve body.

3.6 Cost

Two-piece: Higher, the PTFE seat has a silicone ring inside to increase elasticity and sealing performance.

One-piece: Lower, although the lining process is complex (PTFE has poor elasticity and is difficult to uniformly inject into a one-piece valve body), and manufacturing is challenging, our company has mature technology, resulting in lower prices.

3.7 Application Scenarios

Two-piece : The mainstream choice, most common in chemical, pharmaceutical, wastewater, and corrosive media pipelines.

One-piece : Used in special high-demand applications (such as extremely high sealing requirements and no maintenance needs), but less commonly used in PTFE fully lined butterfly valves.

Post time: Jan-16-2026