Resilient butterfly valves are the most widely used type of butterfly valve in industrial pipelines. They use elastic materials such as rubber as the sealing surface, relying on "material resilience" and "structural compression" to achieve sealing performance.

This article not only introduces the structure, uses, and materials, but also analyzes them from general knowledge to in-depth logic.

1. Basic Understanding of Resilient Butterfly Valves (Brief Description)

1.1 Basic Structure

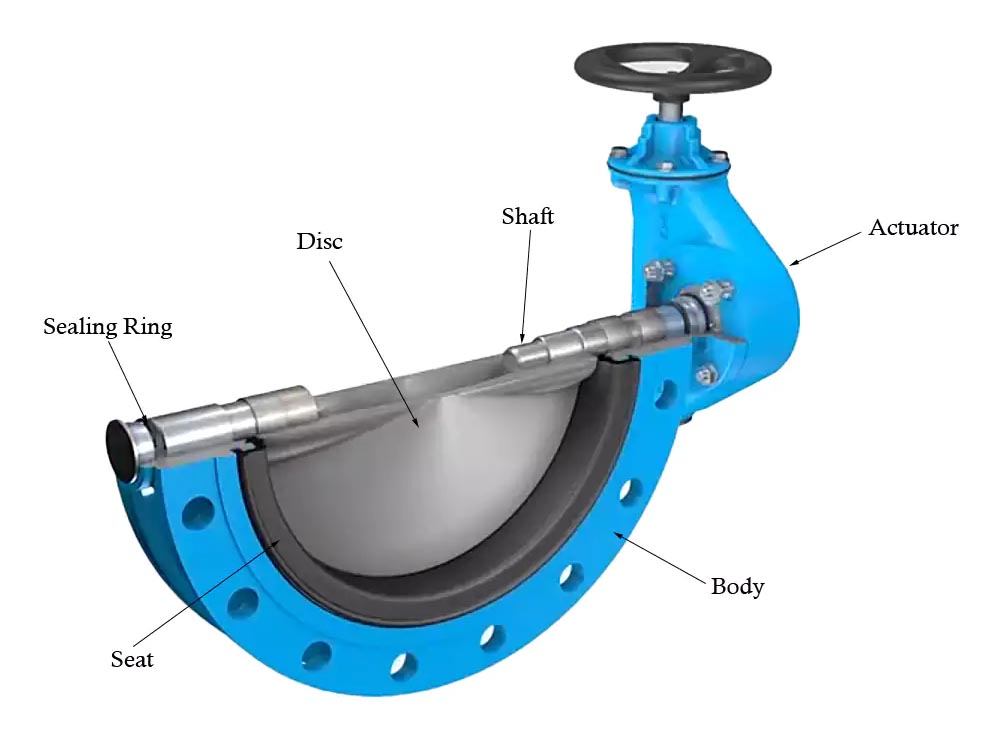

Valve Body: Usually wafer type, lug type, or flanged type.

Valve Disc: A circular metal plate that compresses the rubber seat when closed to create a seal.

Valve Seat: Made of elastic materials such as NBR/EPDM/PTFE/Rubber Lined, working in conjunction with the valve disc.

Valve Stem: Mostly uses a single-shaft or double-shaft design.

Actuator: Handle, worm gear, electric, pneumatic, etc.

1.2 Common Features

Sealing level usually achieves zero leakage.

Low cost and wide range of applications.

Mostly used in low to medium pressure systems such as water, air conditioning, HVAC, and light chemical industries.

2. Misconceptions about Resilient Butterfly Valves

2.1 The essence of sealing is rubber resilience

Many people believe: "Resilient seats rely on rubber resilience for sealing."

The true essence of sealing is:

Valve body + valve stem center distance + valve disc thickness + valve seat embedding method

Together create a "controlled compression zone".

Simply put:

The rubber cannot be too loose or too tight; it relies on a "sealing compression zone" controlled by machining precision.

Why is this crucial?

Insufficient compression: Valve leaks when closed.

Excessive compression: Extremely high torque, premature aging of the rubber.

2.2 Is a more streamlined disc shape more energy-efficient?

Common view: Streamlined valve discs can reduce pressure loss.

This is true according to "fluid mechanics" theory, but it is not entirely applicable to the actual application of Resilient Butterfly Valves.

Reason:

The main source of pressure loss in butterfly valves is not the shape of the valve disc, but the "micro-channel tunnel effect" caused by the contraction of the valve seat rubber. The valve disc being too thin can fail to provide sufficient contact pressure, potentially leading to discontinuous sealing lines and leakage.

A streamlined valve disc can cause sharp points of stress on the rubber, reducing its lifespan.

Therefore, the design of soft-seated butterfly valves prioritizes "sealing line stability" over streamlining.

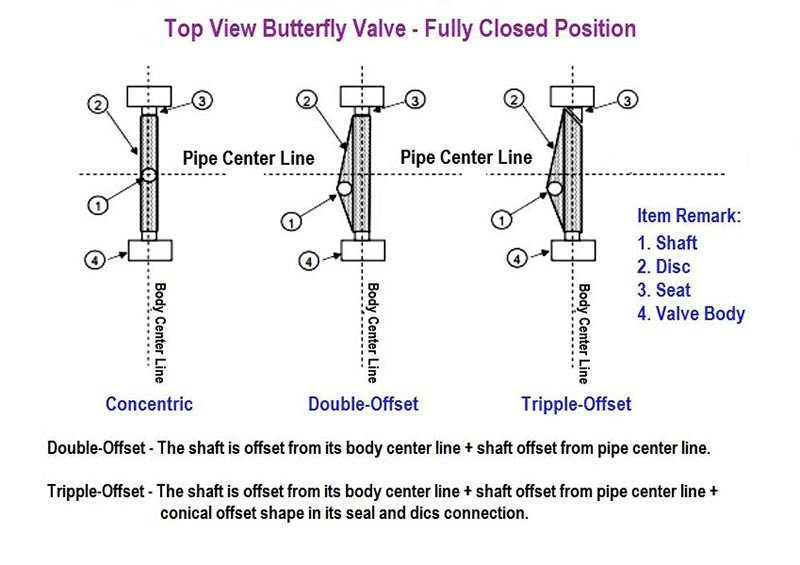

2.3 Soft-seated butterfly valves only have a centerline structure

It is often said online that eccentric butterfly valves should use metal hard seals.

However, real-world engineering experience shows that:

Double eccentricity significantly improves the lifespan of Resilient Butterfly Valves.

Reason:

Double eccentricity: The valve disc only contacts the rubber during the last 2-3° of closing, significantly reducing friction.

Lower torque, leading to more economical actuator selection.

2.4 The main consideration for the rubber seat is the "material name"*

Most users only focus on:

EPDM

NBR

Viton (FKM)

But what truly affects the lifespan is:

2.4.1 Shore hardness:

For example, the Shore A hardness of EPDM is not a case of "the softer the better." Usually, 65-75 is the optimal balance point, achieving zero leakage at low pressure (PN10-16).

Too soft: Low torque but easily torn. In high-pressure peaks (>2 MPa) or turbulent environments, soft rubber is excessively compressed, causing extrusion deformation. Furthermore, high temperatures (>80°C) further soften the rubber.

Too hard: Difficult to seal, especially in low-pressure systems (<1 MPa), where the rubber cannot be sufficiently compressed to form an airtight interface, leading to micro-leakage.

2.4.2 Vulcanization temperature and curing time

Vulcanization temperature and curing time control the cross-linking of rubber molecular chains, directly affecting the stability of the network structure and long-term performance. Typical range is 140-160°C, 30-60 minutes. Too high or too low temperatures lead to uneven curing and accelerated aging. Our company generally uses multi-stage vulcanization (pre-curing at 140°C, followed by post-curing at 150°C). 2.4.3 Compression Set

Compression set refers to the proportion of permanent deformation that rubber undergoes under constant stress (usually 25%-50% compression, tested at 70°C/22h, ASTM D395) and cannot fully recover. The ideal value for compression set is <20%. This value is the "bottleneck" for long-term sealing of the valve; long-term high pressure leads to permanent gaps, forming leakage points.

2.4.4 Tensile Strength

A. Tensile Strength (usually >10 MPa, ASTM D412) is the maximum stress the rubber can withstand before tensile fracture, and is critical for the wear resistance and tear resistance of the valve seat. The rubber content and carbon black ratio determine the tensile strength of the valve seat.

In butterfly valves, it resists shearing by the valve disc edge and fluid impact.

2.4.5 The biggest hidden danger of butterfly valves is leakage.

In engineering accidents, leakage is often not the biggest problem, but rather the increase in torque.

What truly leads to system failure is:

Sudden surge in torque → worm gear damage → actuator tripping → valve jamming

Why does the torque suddenly increase?

- High-temperature expansion of the valve seat

- Water absorption and expansion of the rubber (especially low-quality EPDM)

- Permanent deformation of the rubber due to long-term compression

- Improper design of the gap between the valve stem and valve disc

- Valve seat not properly broken in after replacement

Therefore, the "torque curve" is a very important indicator.

2.4.6 Valve body machining accuracy is not unimportant.

Many people mistakenly believe that the sealing of soft-seated butterfly valves mainly relies on rubber, so the machining accuracy requirements of the valve body are not high.

This is completely wrong.

The accuracy of the valve body affects:

Valve seat groove depth → sealing compression deviation, easily causing misalignment during opening and closing.

Insufficient chamfering of the groove edge → scratching during valve seat installation

Error in the center distance of the valve disc → localized excessive contact

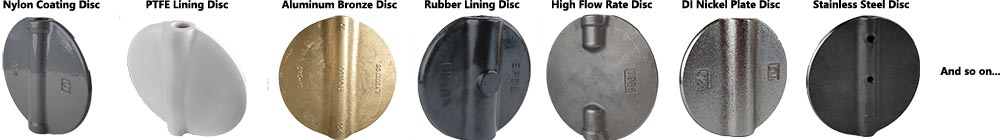

2.4.7 The core of "fully rubber/PTFE lined butterfly valves" is the valve disc.

The core of the fully rubber or PTFE lined structure is not to "have a larger area that appears corrosion-resistant," but to block the medium from entering the micro-channels inside the valve body. Many problems with inexpensive butterfly valves are not due to poor rubber quality, but rather:

The "wedge-shaped gap" at the junction of the valve seat and body is not properly addressed.

Long-term fluid erosion → microcracks → rubber blistering and bulging

The final step is localized failure of the valve seat.

3. Why are Resilient Butterfly Valves used worldwide?

Besides low cost, the three deeper reasons are:

3.1. Extremely high fault tolerance

Compared to metal seals, rubber seals, due to their excellent elasticity, have a strong tolerance for installation deviations and slight deformations.

Even pipe prefabrication errors, flange deviations, and uneven bolt stress are absorbed by the elasticity of the rubber (of course, this is limited and undesirable, and will cause some damage to the pipeline and valve in the long run).

3.2. Best adaptability to system pressure fluctuations

Rubber seals are not as "brittle" as metal seals; they automatically compensate the sealing line during pressure fluctuations.

3.3. Lowest total life cycle cost

Hard-sealed butterfly valves are more durable, but the cost and actuator costs are higher.

In comparison, the overall investment and maintenance costs of Resilient Butterfly Valves are more economical.

4. Conclusion

The value of Resilient Butterfly Valves is not just "soft sealing"

Soft-sealed butterfly valves may seem simple, but truly excellent products are backed by engineering-grade rigorous logic, including:

Precise compression zone design

Controlled rubber performance

Geometric matching of valve body and stem

Valve seat assembly process

Torque management

Life cycle testing

These are the key factors determining quality, not "material name" and "appearance structure".

NOTE:* DATA refers to this website: https://zfavalves.com/blog/key-factors-that-determine-the-quality-of-soft-seal-butterfly-valves/

Post time: Dec-09-2025