A butterfly valve undergoes numerous tests from manufacturing to shipment to ensure its quality and reliability. The comprehensive inspection covers standard items such as material, coating, appearance, rubber, pressure, and dimensions, as well as sealing performance, appearance, torque, hardness, thickness, assembly, thread and flange precision, and traceability markings.

The inspection process can be conducted in the following order: Raw material inspection → Processing inspection → Finished product performance testing → Final acceptance. Each aspect is explained in conjunction with specific methods and standards.

Butterfly Valve Inspection Procedure

1. Raw Material Inspection

1.1 Purpose

To confirm that the raw materials such as the valve body, valve plate, valve stem, and sealing ring meet the standard requirements.

1.2 Inspection Items:

-Chemical Composition Analysis: Using a spectrometer or chemical analysis method, verify the material certificate to confirm compliance with ASTM/GB/EN material standards.

-Mechanical Performance Testing: Sampling is performed for tensile, yield, elongation, and impact tests.

-Material Identification and Traceability: Each batch of raw materials must be identified by its furnace number to ensure traceability of origin.

-Metallographic Inspection (Optional): Inspect castings for defects such as slag inclusions and porosity.

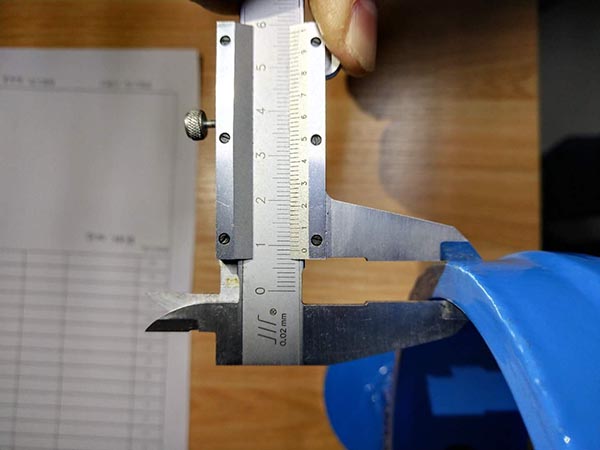

2. Dimensional Inspection

Tools: Vernier calipers, inside diameter gauge, depth gauge.

2.1 Purpose

To ensure product dimensions match standard drawings for easy installation and interchangeability.

2.2 Inspection Items

Valve body length (face-to-face dimension)

Flange connection hole spacing, hole diameter, thread specification

Valve plate thickness and edge clearance

Thread depth and tolerance

3. Rubber & Seat Inspection

Common Materials: EPDM, NBR, VITON, PTFE.

3.1 Purpose

To ensure the pressure resistance, temperature resistance, and corrosion resistance of sealing materials.

3.2 Inspection Items

Material Confirmation

Check surface smoothness, absence of burrs, bubbles, and impurities.

Inspect key dimensions of the sealing ring, such as cross-sectional diameter and inner and outer diameters.

Rubber hardness (Shore hardness tester), compression set, tensile strength, etc.

Abrasion resistance test

Valve plate fit and integrity

4. Coating Inspection

4.1 Purpose

To ensure corrosion resistance, adhesion, and coating thickness meet standards.

4.2 Inspection Items

Surface pretreatment (rust removal) grade before spraying (Sa2.5 or above, no visible scale or rust)

Coating thickness after spraying (using a coating thickness gauge)

Coating adhesion (cross-cut test, 1mm spacing, coating peel-off area ≤5% after tape removal)

Appearance inspection (sags, pinholes, bubbles, orange peel, color difference)

Coating hardness and corrosion resistance salt spray test

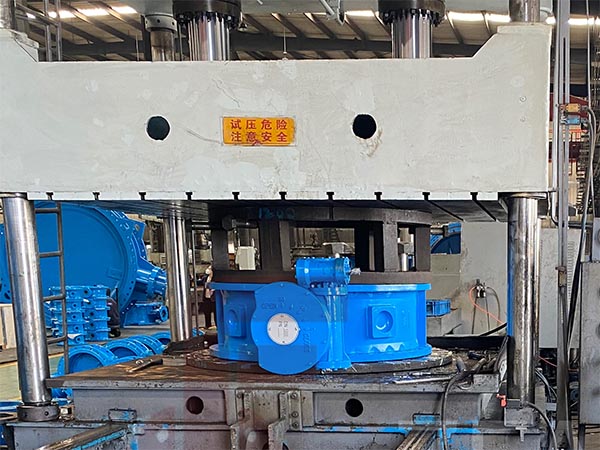

5. Pressure & Leak Test

5.1 Purpose

To ensure the valve is leak-free under rated pressure.

5.2 Acceptance Criteria

The valve body and all pressure-bearing components must not have any structural damage, permanent deformation, or leakage.

5.3 Test Items

Shell Strength Test: Hydrostatic test at 1.5 times rated pressure, holding time ≥ 2 minutes.

Sealing Test: Forward and reverse sealing test at 1.1 times rated pressure.

Air Tightness Test: Detect micro-leakage using air or nitrogen at 0.6 MPa.

Zero Leakage Standard: Complies with API 598 / ISO 5208 requirements.

6. Operating Torque Test

6.1 Purpose

To verify whether the opening and closing torque meets the standard and is within the design requirements, ensuring the drive unit is matched.

Testing Method

Measured using torque wrenches and torque meters such as electric actuators; compare the design torque with the measured torque.

7. Visual & Marking Check

7.1 Purpose

To ensure appearance quality and marking specifications.

7.2 Test Items

No iron filings, welding slag, oil stains, or other impurities inside.

No cracks, burrs, or rust. Surface smoothness and color consistency. Nameplate information (model, pressure rating, material, flow direction arrow) is clear, complete, and secure.

8. Functional Test

8.1 Purpose

To verify the reliability and flow performance of the valve.

8.2 Test Items

Valve plate opening and closing flexibility

Valve position positioning accuracy

Flow resistance coefficient (Cv value) measurement

Fluid flow direction consistency

9. Final Inspection and Factory Inspection

9.1 Purpose

To comprehensively determine whether the product is qualified and ready for shipment.

9.2 Includes

Review of test records

Affixing of certificate of conformity and test labels

Whether the packaging effectively protects against damage during transportation, and whether there are protective caps on the flange face and threaded ends.

Post time: Oct-28-2025