In the industrial fluid control sector, butterfly valves play a critical role in regulating, directing, and isolating the flow of liquids, gases, and slurries in pipelines. A flanged butterfly valve is one type of connection type, featuring integral flanges on both ends of the valve body, allowing for secure bolted connections to pipe flanges.

The quarter-turn rotation mechanism of a flanged butterfly valve distinguishes it from linear valves such as gate or globe valves, offering advantages in speed and space efficiency.

This article will delve into the details of flanged butterfly valves, covering their design, types, materials, applications, advantages and disadvantages, installation, maintenance, comparisons with other valves, and future trends.

1. Definition and Operating Principle

A flanged butterfly valve is a 90-degree rotational motion valve characterized by a disc that controls fluid flow through stem rotation. The valve body features flanges on both ends for direct bolted connections to the pipeline. Flange butterfly valves feature raised or flat flanges with bolt holes, providing a more robust and stable connection suitable for low, medium, and high-pressure applications, as well as small, medium, and large diameters.

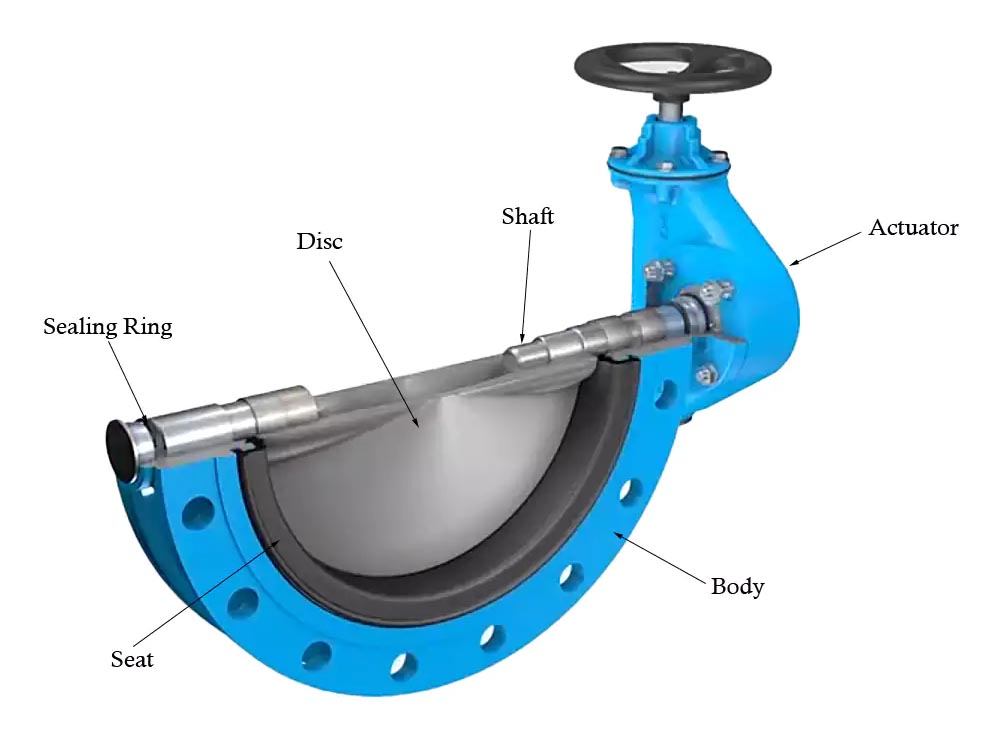

The operating principle is simple and effective. A valve consists of a valve body, valve disc, valve stem, valve seat, and actuator. When a handle or gear is operated, or the valve stem is rotated by an automatic actuator, the valve disc rotates from a position parallel to the flow path (fully open) to a perpendicular position (fully closed). In the open position, the valve disc is aligned with the pipeline axis, minimizing flow resistance and pressure loss. When closed, the valve disc seals against the seat inside the valve body.

This mechanism allows for rapid valve operation, typically requiring only a 90-degree rotation, making it faster than multi-turn valves. Flanged butterfly valves can handle bidirectional flow and are typically equipped with resilient or metal seats to ensure tight shutoff. Their design makes them particularly suitable for systems requiring frequent switching or where space is limited.

2. Components

Main components include:

- Valve Body: The outer housing, typically a double-flange construction, provides structural connections and houses the internal components. Carbon steel is used for general use, stainless steel for corrosion resistance, nickel-aluminum bronze for marine environments, and alloy steel for extreme conditions.

- Valve Disc: The rotating element, available in either streamlined or flat designs, controls the flow. The disc can be centered or offset to enhance performance. Stainless steel, aluminum bronze, or coated with nylon for improved wear resistance.

- Stem: The shaft connecting the valve disc to the actuator transmits rotational force. Stainless steel or high-strength alloys withstand torque.

Through-shaft or two-piece stems are commonly used, equipped with seals to prevent leakage.

- Seat: The sealing surface is made of an elastomeric material such as EPDM or PTFE. EPDM (-20°F to 250°F), BUNA-N (0°F to 200°F), Viton (-10°F to 400°F), or PTFE (-100°F to 450°F) is used for soft seals; metallic materials such as stainless steel or Inconel are used for high-temperature hard seals.

- Actuator: Operated manually (handle, gear) or powered (pneumatic, electric).

- Packing and gaskets: Ensure leak-tight seals between components and at flange connections.

These components work together to provide reliable flow control.

3. Types of Flanged Butterfly Valves

Flanged butterfly valves can be categorized as follows based on disc alignment, actuation method, and body type.

3.1 Alignment

- Concentric (zero offset): The valve stem extends through the center of the disc and features a resilient seat. This valve is suitable for low-pressure applications with temperatures up to 250°F.

- Double offset: The valve stem is offset behind the disc and off-center, reducing seat wear. This valve is suitable for medium-pressure applications and temperatures up to 400°F.

- Triple offset: The increased tapered seat angle creates a metal-to-metal seal. This valve is suitable for high-pressure (up to Class 600) and high-temperature (up to 1200°F) applications and meets zero-leakage requirements.

3.2 Actuation Method

Actuation types include manual, pneumatic, electric, and hydraulic to accommodate various operating requirements.

4. Industry Applications

Flanged butterfly valves are widely used in the following sectors:

- Water and Wastewater Treatment: Used for flow regulation in treatment plants and diversion systems. - Chemical Processing: Handling acids, alkalis, and solvents requires corrosion-resistant materials.

- Oil & Gas: Piping for crude oil, natural gas, and refining processes.

- HVAC Systems: Controls air and water flow in heating and cooling networks.

- Power Generation: Manages steam, cooling water, and fuel.

- Food & Beverage: Hygienic design for aseptic fluid handling.

- Pharmaceutical: Precise control in sterile environments.

- Marine & Pulp & Paper: Used for seawater, pulp, and chemical processing.

5. Advantages and Disadvantages of Flange Butterfly Valves

5.1 Advantages:

- Compact and lightweight, reducing installation costs and space requirements.

- Quick quarter-turn operation and rapid response.

- Lower cost for larger diameters.

- Low pressure loss when open, energy-efficient and efficient.

- Suitable for fluid switching with excellent sealing performance.

- Easy to maintain and compatible with automation systems.

5.2 Disadvantages:

- The valve disc blocks the flow path when open, resulting in some pressure loss. - Limited throttling capacity in high-pressure applications, potentially causing cavitation.

- Soft valve seats wear more quickly in abrasive media.

- Closing too quickly may cause some water hammer.

- Some designs require higher initial torques, requiring stronger actuators.

6. How to Install a Butterfly Valve

During installation, align the valve flange with the pipe flange, ensuring that the bolt holes match.

Insert a gasket for sealing.

Secure with bolts and nuts, tightening evenly to prevent distortion.

Double-flange valves require alignment of both sides simultaneously; lug-type valves can be bolted one side at a time.

Check the disc's freedom of movement by cycling the valve before pressurizing.

When installed vertically, the valve stem should be positioned horizontally to prevent sediment accumulation.

Always follow the manufacturer's guidelines and testing standards such as API 598.

7. Standards and Regulations

Flanged butterfly valves must comply with safety and interoperability standards:

- Design: API 609, EN 593, ASME B16.34. - Testing: API 598, EN 12266-1, ISO 5208.

- Flanges: ASME B16.5, DIN, JIS.

- Certifications: CE, SIL3, API 607 (fire safety).

8. Comparison with Other Valves

Compared to gate valves, flanged butterfly valves operate faster and offer throttling capabilities, but are slightly less resistant to flow.

Compared to ball valves, they are more economical for larger diameters, but experience higher pressure loss during opening.

Globe valves offer better precision throttling, but are larger and more expensive.

Overall, butterfly valves excel in space-constrained and cost-sensitive applications.